Company NewsMore >>

-

10-04 2024

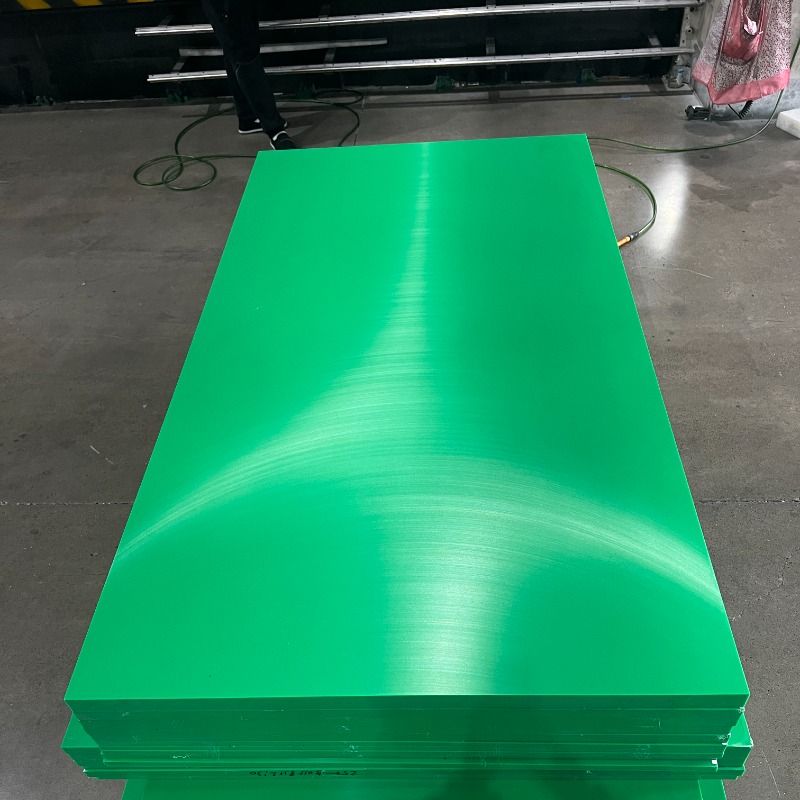

UHMWPE Process Parts

UHMWPE Process Parts UHMWPE is often described as the world's toughest polymer. UHMWPE is characterized by toughness, chemical resistance, low coefficient of friction, near zero moisture absorption, and easy processing.We provides custom plastic CNC machining service.We're your ideal partner to create precision machined prototypes and parts. UHMWPE Process Parts compared to other solid thermoplastics, UHMW is lightweight and floats on water. Most importantly, UHMW machined parts are self-lubricating and have the highest impact and wear resistance of any thermoplastic. UHMWPE Process Parts Impact-resistant preservatives reduce stress and installation time. UHMWPE is a common plastic known for its extreme durability, versatility, and cost-effectiveness. You can also count on UHMW parts for their reliable wear, impact, and chemical resistance. Order your custom CNC machined UHMW parts today in just minutes.

-

09-20 2024

What can you make with UHMW parts?

What can you make with UHMW parts? UHMW is also easy to machine with common woodworking tools, one of the contributing factors to its cost-effectiveness. The truly surprising thing about parts made from UHMW is that they often outperform metal parts in specific applications. As with other plastics like HDPE, UHMW is an excellent fit for marine construction applications for things like dock fender pads, pile guards, and anti-skid walkways. Similarly, these two materials tend to replace wood in these scenarios and they do not rot, splinter, or corrode like wood.

-

06-12 2024

UHMWPE processed parts

Shandong Shengte'er wear-resistant UPE machining parts manufacturer uses pure new raw materials to make UHMWPE plates and bars, which are then processed and produced by advanced precision CNC equipment. Each piece is high-quality and cost-effective, and wear-resistant UPE machining parts are customized according to the drawings and directly shipped by the manufacturer. Shandong Shengte'er wear-resistant UPE machined parts have high toughness, good aging resistance, good mechanical vibration reduction ability, good sliding performance, excellent wear resistance, good mechanical processing performance, good corrosion resistance, and higher mechanical strength, stiffness, and hardness compared to other plastics. When used for precise and effective control, there is no creep phenomenon and good dimensional stability.

-

03-22 2024

the used to shape UHMWPE processed parts

The processing technology of ultra-high molecular weight polyethylene (UHMW-PE) has rapidly developed.

Industry NewsMore >>

-

03-28 2025

Advantages and application areas of UHMWPE liner

Advantages and application areas of UHMWPE liner Advantages of UHMWPE liner: 1. high wear resistance and low coefficient of friction, to prevent material flow obstruction; 2. non-absorbent, not affected by the humidity of the material; 3. very low coefficient of friction, so that the adhesion is large, not easy to free flow of bulk material flow smoothly; 4. protection of the equipment, not corroded by the material caused by equipment failures; 5. lightweight, only 1/8 of the steel, easy to repair and replacement. UHMWPE lining application areas: Widely used in the mining industry, coal processing plants, metallurgical industry, thermal power plants, shipbuilding industry and other sectors of the transportation of liquids, solids, solid-liquid mixtures of funnels, funnels, tipping boards, scraper conveyor skid, jigger screen plate, flotation machine liner, ship cargo hold liner, large skid, mining trucks, tipper carriages lining, etc. Wear-resistant corrosion-resistant applications, with the unique advantage of value for money.

-

04-01 2025

Application areas of UHMWPE outrigger plate

Application areas of UHMWPE outrigger plate 1. Mining and heavy machinery: In mining, dock and other heavy-duty operations, UHMWPE outrigger plates can effectively carry heavy loads and reduce equipment damage and maintenance costs. 2. Aerospace and aviation: Because of its superior wear and impact resistance, UHMWPE outrigger plates are also used in part of the structure of the space shuttle and aircraft support components. 3. chemical and pharmaceutical industry: due to its excellent chemical stability, UHMWPE is widely used in chemical pipelines, tanks and pharmaceutical equipment. 4. construction and engineering: in construction, UHMWPE outrigger plates are commonly used in load-bearing structures and vibration-damping facilities, which can improve the safety and stability of the building. 5. Transportation and logistics: In logistics management, UHMWPE outrigger plates are used in forklifts, lifts and storage equipment to provide support and ensure the smooth progress of transportation.

-

03-25 2025

Flame retardant antistatic paving mat

Flame retardant antistatic paving mat Flame retardant antistatic paving mat is a kind of paving material specially designed for the harsh environment such as underground coal mine, with multiple properties such as flame retardant, antistatic, wear-resistant, corrosion-resistant, etc., which is very suitable to be used as temporary paving material for underground coal mine. Flame retardant and antistatic paving matting is added with flame retardant and antistatic materials during the manufacturing process. Polyethylene itself has excellent chemical stability and impact resistance. By adding flame retardant and antistatic materials, the paving mat has flame retardant and antistatic properties while maintaining its original mechanical properties. The flame retardant and antistatic paving mat adopts special flame retardant material and process, which can effectively reduce the flammability of the material and reduce the probability of fire. Once encountering an open fire or high temperature heat source, it can quickly form a carbonized layer, effectively isolating oxygen and preventing the fire from spreading. At the same time, the amount of toxic gases released during the combustion process is very small, posing no threat to the lives of miners. This characteristic is especially important in the flammable and explosive environment such as underground coal mines.

-

03-19 2025

how can we pick the excellent UHMWPE sheets?

With the wide application of composite plastics, UHMWPE sheets are also gradually coming to our vision, before we use UHMWPE sheets, how to pick the excellent product is our concern, below I organize the relevant instructions for you. UHMWPE sheets is a kind of high-quality polymer sheet, about its ultra-high performance, I believe we are not unfamiliar with it, then how can we pick the excellent UHMWPE sheets? First of all, we can look at the surface gloss of UHMWPE sheets, poor gloss is recycled plastic. In our selection of UHMWPE sheet, we can also look at his toughness, recycled plastic is also much worse. Furthermore, how the light transmission is not very good, then it is recycled plastic. Want to choose the right UHMWPE sheet, there are also the following tips can be applied, we can heat its welding, recycled plastic welding will have smoke. Look at its cutting surface recycled plastic cut inside will have different colors of miscellaneous materials. We can also judge by the density, throw the water to see if it is floating on the water surface, most of the recycled ones are sinking. Look at the toughness of UHMWPE board, pure raw material PP polypropylene plastic board toughness is extremely good can be slightly bent.