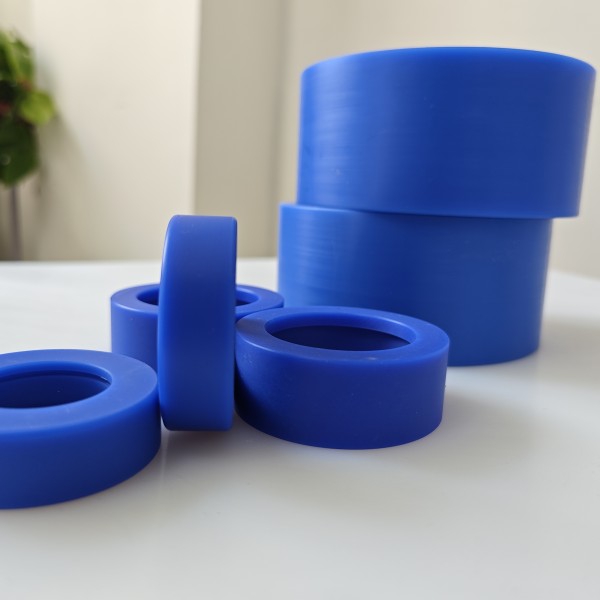

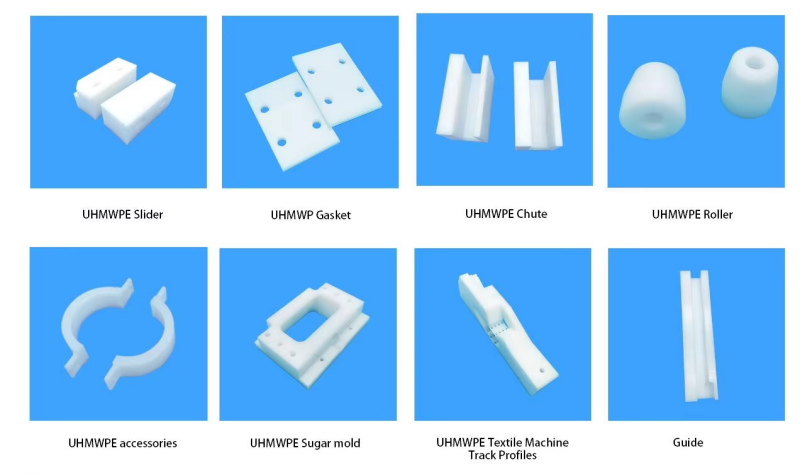

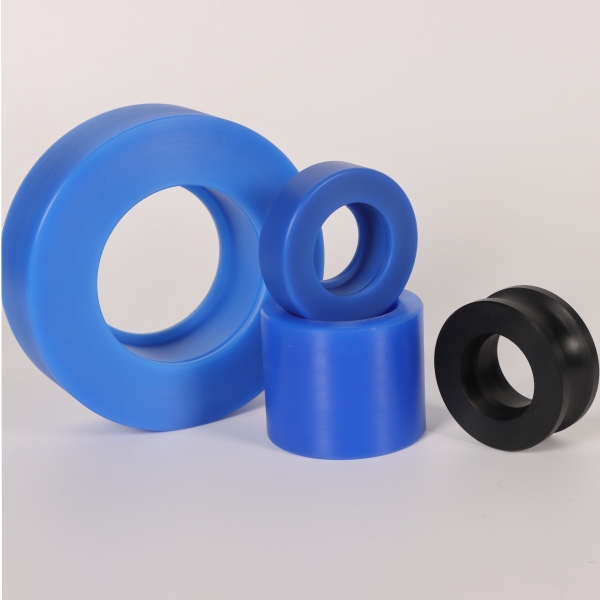

PE 1000 Plastic UHMWPE Machining Pulley For Sale

Brand STE PLASTIC

Product origin ShanDong China

Delivery time Within 15 Days

Supply capacity Factory Direct Supply

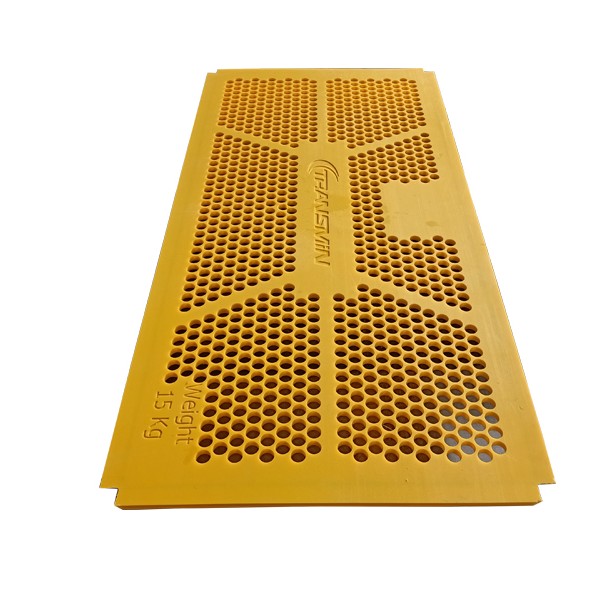

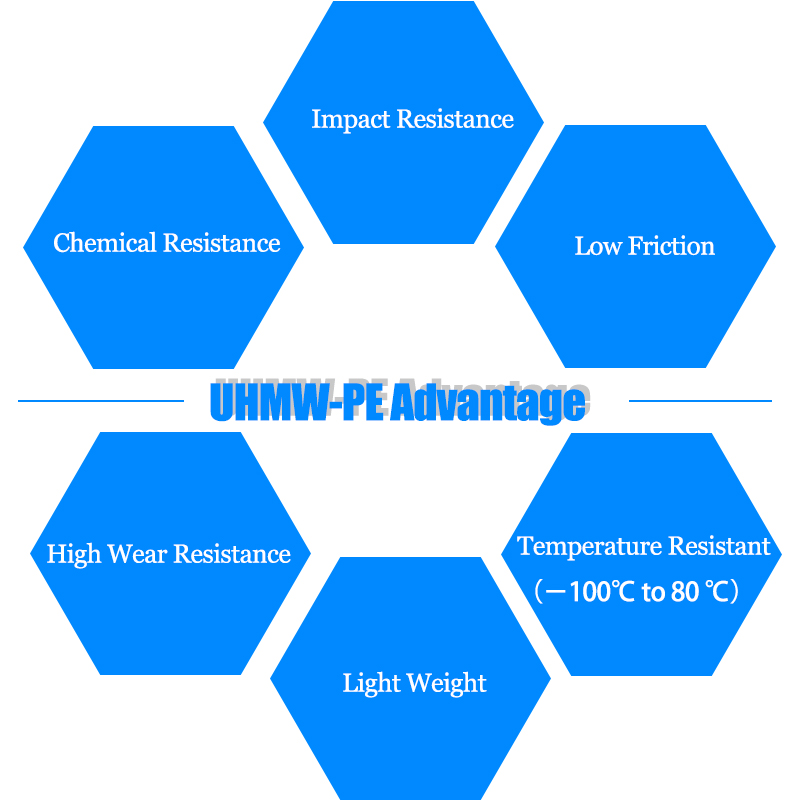

Ultra high molecular weight polyethylene (UHMWPE) is an engineering plastic with extremely high wear resistance and high elastic modulus, which is widely used in the manufacturing of various wear-resistant pulleys.

Characteristics of polyethylene pulleys

High strength, able to withstand loads for a long time;

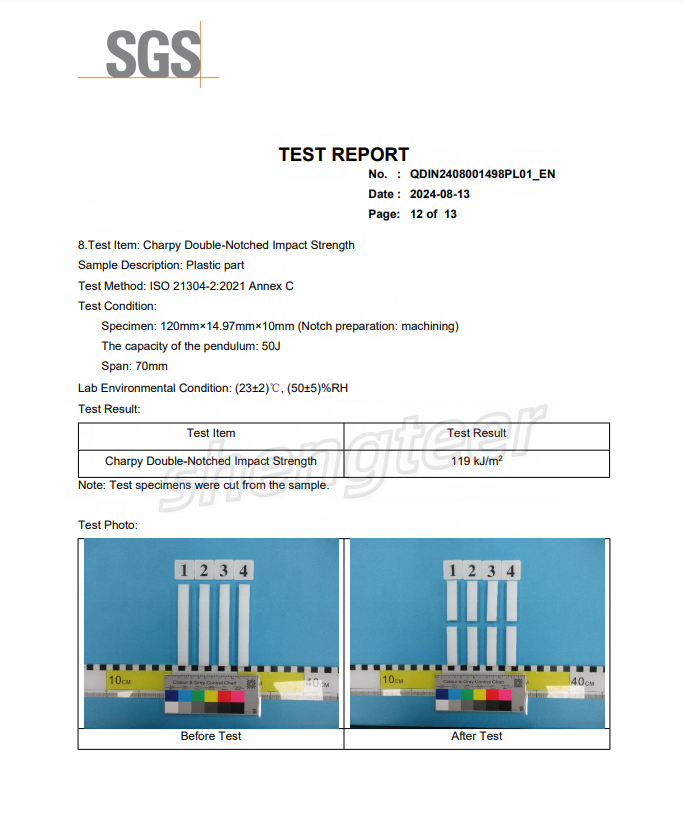

Good resilience, can bend without deformation, while maintaining toughness and resisting repeated impacts;

Wear resistant, self-lubricating, with better performance than bronze, cast iron, carbon steel, and phenolic pressure plates in oil-free or (deoiled) lubrication applications, reducing consumption and saving energy;

Sound absorption and shock absorption, MC nylon has a much smaller modulus than metal, and has a greater vibration reduction amplitude, providing a more practical way to prevent noise than metal.

No | Item | Unit | MC |

1 | density | G/CM3 | 1.15 |

2 | Hardness | Rocwell | R120 |

3 | Tensile strength | Mpa | 82 |

4 | elongation | % | 36 |

5 | Modulus of elasticity (compression) | Mpa | 2.8 |

6 | The bending strength | Mpa | 116 |

7 | The compression strength | MPa | 112 |

8 | The impact strength | Kg-cm/cm | 3.5 |

9 | Bibulous rate | % | 1 |

10 | Crystallinity | % | 50 |

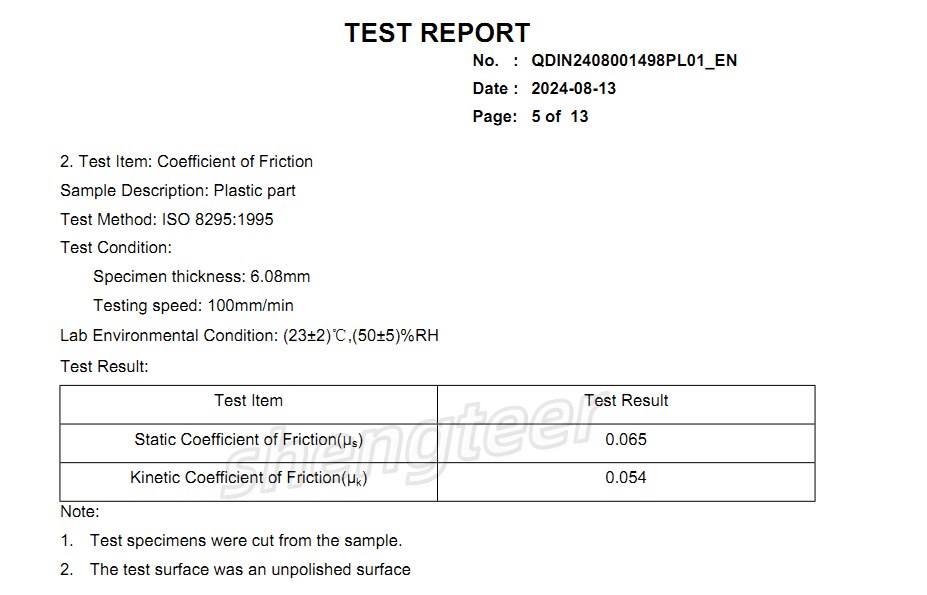

11 | Coefficient of friction (for steel) | 10-4/C | 0.32 |

12 | Dielectric constant | 1000Hertz | 3.4 |

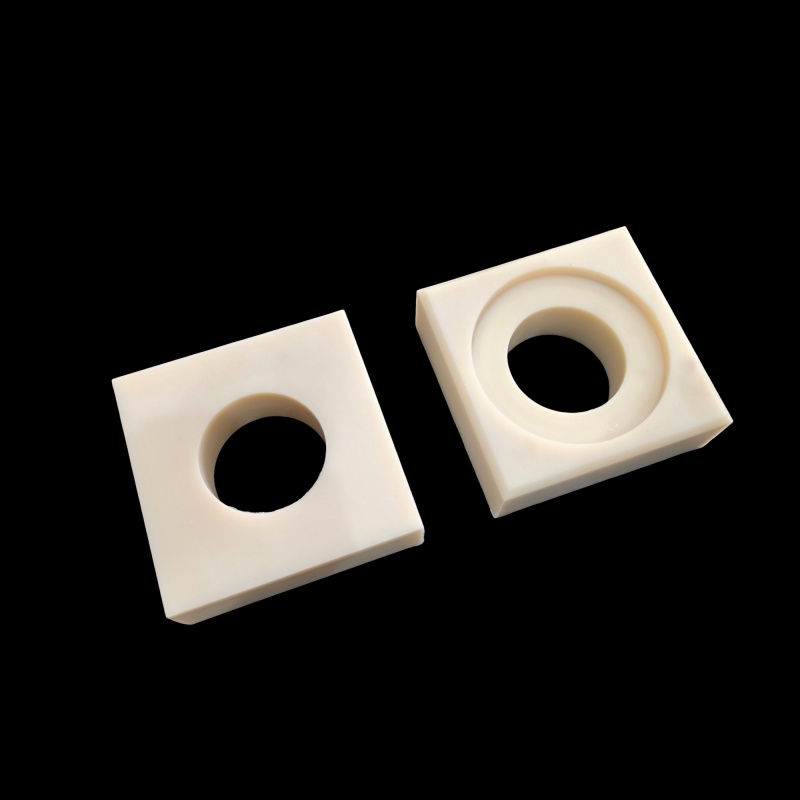

The application field of polyethylene pulleys:

Widely used in wear-resistant parts of mechanical equipment, replacing metal materials such as copper and alloy to make wear-resistant transmission parts. Suitable for household appliances. Automotive parts, chemical machinery parts, food machinery parts, aerospace, steel industry, engineering machinery parts.

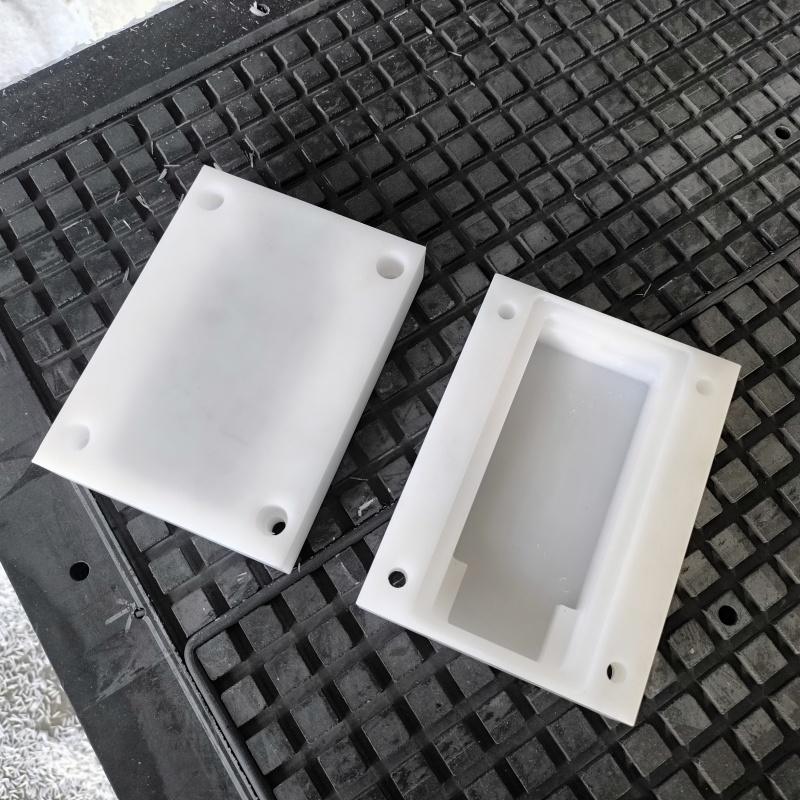

Properties :

Excellent performance on abrasion resistant;

High impact strength;

Excellent chemical resistant;

Do not absorb moisture ,water and chemical liquid;

Food direct safty;

Stress crack resistant.