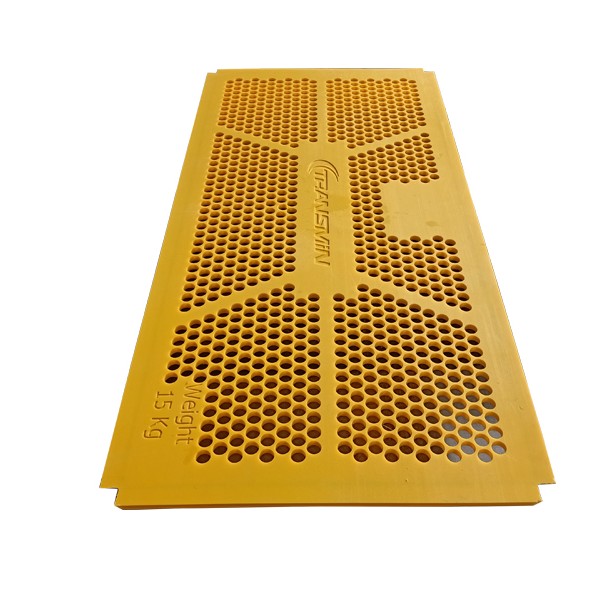

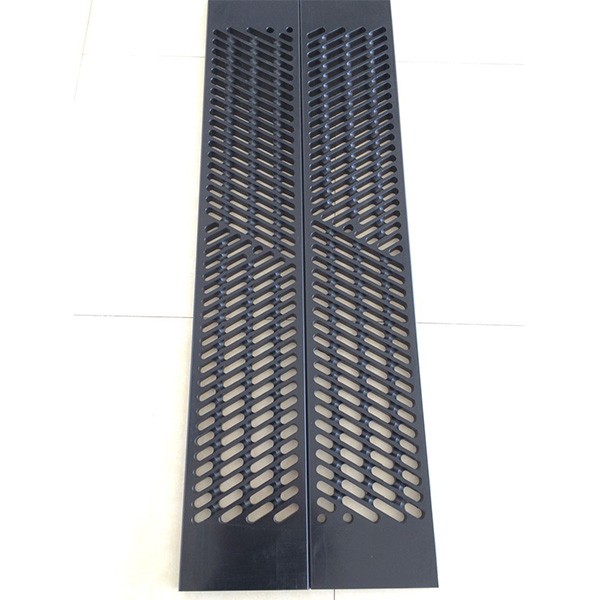

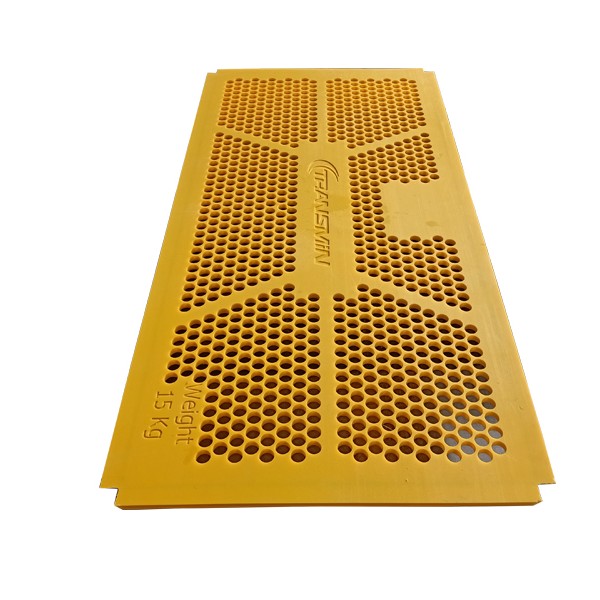

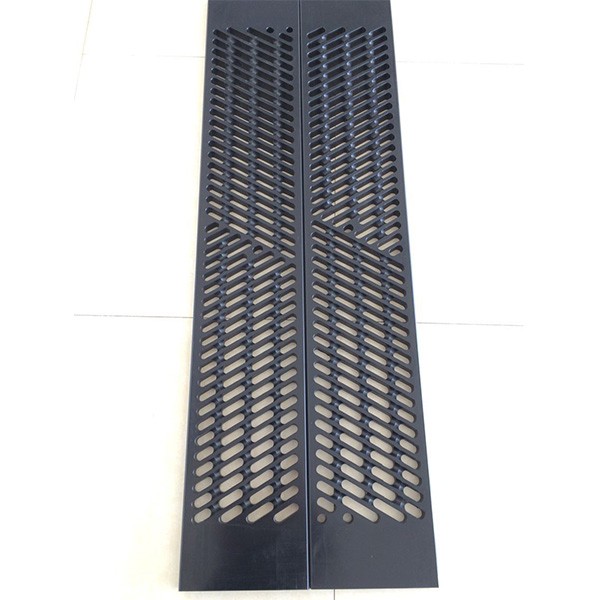

UHMWPE Suction Box Top Cover For Paper Machine

Brand STE PLASTIC

Product origin ShanDong China

Delivery time Within 15 Days

Supply capacity Factory Direct Supply

The cover plate of the vacuum suction tank is made of polymer polyethylene material, and the average service life of the formed mesh has been increased from 9.5 days to 18.6 days, an increase of 90%, improving the mechanical operation results.

The cover plate, panel, and mechanical components of the suction tank all require high wear resistance. High molecular weight polyethylene material is an environmentally friendly thermoplastic that combines the superior properties of plastic and is used as a substitute for materials such as steel plates and bronze in industries such as textiles, paper making, and food machinery.

The use temperature of the PE scraper for the UPE suction tank cover plate is 100-110 ℃. Good cold resistance, can be used at -269 ℃. The product with a density of 0.985g/cm3 and a molecular weight of 2 million has a tensile strength at break of 40MPa, an elongation at break of 350%, a bending modulus of elasticity of 600MPa, and a continuous impact on the notch of the cantilever beam. Abrasion (MPC method) 20mm.

1. Reduced the number of shutdowns due to screen changes, reduced maintenance rates, and improved the service life of the paper machine.

2. Acid and alkali corrosion resistance, wear resistance, good fatigue resistance, self-lubrication, impact resistance, low friction coefficient, and oxidation resistance.

3.Due to the non hygroscopicity of polymer polyethylene materials, the service life of polyester forming nets and towels in paper machines has been extended, the drag load of forming nets has been reduced, and the self lubrication of the forming nets has reduced power consumption. The cover plate of the polymer polyethylene suction tank also has particularly high wear resistance, greatly extending the service life of the vacuum suction tank.