-

03-11 2025

Shipment Of UHMWPE sheet to Southeast Asia

Shipment Of UHMWPE sheet to Southeast Asia Size:1500*3000*15mm Uhmwpe sheet shipped to Southeast Asia this week. This batch of UHMWPE sheets covers thicknesses from 5 mm to 50 mm, widths from 1.2 m to 2.2 m, and lengths can be customized up to 6 meters. The sheets are highly wear-resistant, impact-resistant and self-lubricating, and can maintain stable performance in complex industrial environments. It is understood that UHMWPE sheet is widely used in mining, chemical, machinery manufacturing and other industries in Southeast Asia can play an important role, can effectively improve the efficiency of equipment operation and reduce maintenance costs.

-

03-07 2025

UHMWPE Ground protection mat

UHMWPE Ground protection mat In desert areas, the use of paving mats can play a key role and offer the following benefits: 1. Providing a stable driving surface: Desert terrain is less stable and the ground may be sandy or gravelly, and vehicles driving on these terrains are prone to plunging or skidding. Laying paving mats can provide a firm, stable driveway surface to ensure stable vehicle travel. 2. Prevent vehicles from entering dune areas: The use of paving slabs can be used as a road base for vehicle traffic, preventing vehicles from entering unstable dune areas. 3. Reducing disturbance to the ecosystem: The desert is a fragile ecosystem with sparse vegetation, and plants and animals have adapted to the harsh environment. The use of paving mat can reduce the impact of vehicles and equipment on the ground, reduce the interference to the desert ecosystem and protect the ecological balance. 4. Facilitate the movement of equipment: In the desert, large equipment needs to move in a very challenging environment. The use of paving mats can be used as the basis for equipment traveling, helping the equipment to travel more smoothly and improve work efficiency. 5. Improve the camping environment: When conducting field activities and camping, paving matting can provide a level camp ground, reducing the possibility of damage to tents and utensils due to uneven ground. When laying paving slabs, attention needs to be paid to the selection of materials and sizes suitable for desert environments to ensure that they are durable and long-lasting in harsh desert conditions. At the same time, the principle of desert protection needs to be observed to minimize the impact on the desert ecosystem.

-

03-05 2025

PE1000 Sheet

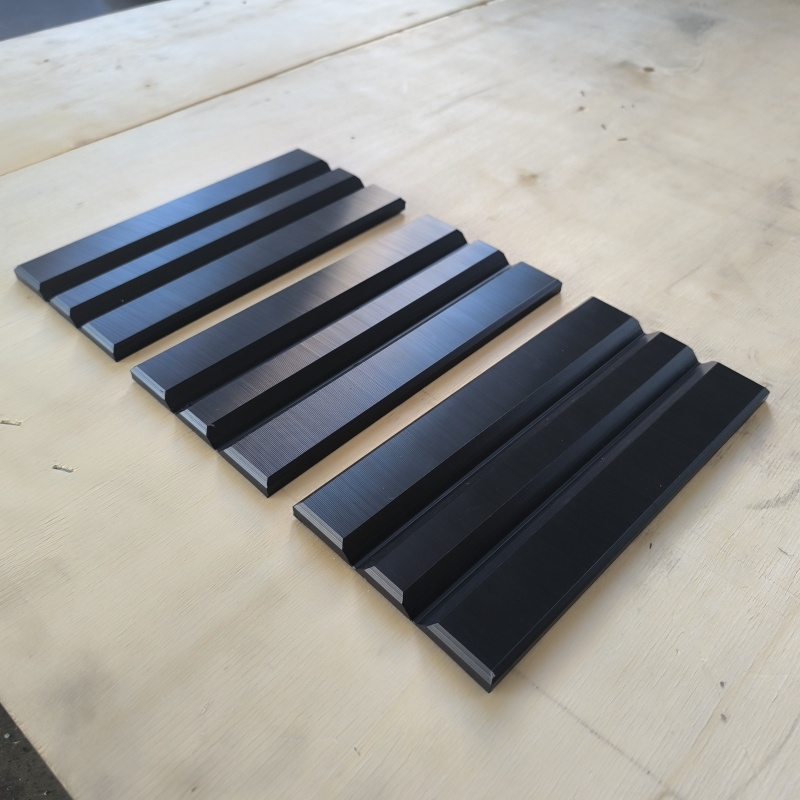

PE1000 Sheet PE1000 Sheet UHMWPE(Ultra High Molecular Weight Polyethylene) has an incredible resistance to abrasion and can out perform almost any engineering plastic in this regard,UHMWPE sheet is well suited for applications that demand durability and low friction. PE1000 Sheet have Outstanding abrasion resistance Superior impact resistance and Exhibits virtually no water absorption.UHMWPE sheet Self-lubricating properties Excellent mechanical properties even in cryogenic conditions.UHMWPE is often described as the world's toughest polymer. UHMWPE is characterized by toughness, chemical resistance, low coefficient of friction, near zero moisture absorption, and easy processing.We provides custom plastic CNC machining service.We're your ideal partner to create precision machined prototypes and parts.

-

02-24 2025

UPE Crane Outrigger Pads

UPE Crane Outrigger Pads Crane outrigger pads are essential safety accessories that provide stability and support for cranes and other heavy lifting equipment on job sites. Choosing the right outrigger pads is crucial to ensure safe and efficient operations. In this article, we’ll explore the various types of crane outrigger pads available in the market, their unique characteristics, and their specific uses to help you make an informed decision for your lifting operations. Custom Outrigger Pads: In addition to standard options, many manufacturers offer custom outrigger pads tailored to specific requirements and preferences. Custom pads can be fabricated to precise dimensions, shapes, and configurations to fit unique outrigger setups and load conditions. Whether you need pads with reinforced corners, integrated handles, or color-coded markings, custom outrigger pads provide flexibility and versatility to meet your exact specifications. Working with a reputable supplier ensures that you get high-quality, custom solutions designed for optimal performance and safety.

-

02-18 2025

Ground protection mat

Ground Protection Mats UHMWPE is best option for Ground Protection mats, not only it's non-toxic and recyclable makes it perfect for environmentally sensitive locations, but also it can distribute the weight of the equipment over a larger area, reducing the impact on the ground.They offer floor protection while allowing heavy equipment to maneuver around the mud, sand, and rough surfaces easily for access. These protective safety mats are an ideal alternative to timber mats made with hardwood, which often break or become unstable.Provides a Secure Base for Equipment Ground protection mats can be implemented to create temporary roadways and site access, provide a secure, stable surface and ground conditions for workers, machinery, and visitors to the site for excellent safety. Matting that doesn’t slip or move, keeps all equipment steady and easy to use without any concern of lack of traction.

-

02-08 2025

Shipment Of UHMWPE sheet to Europe

Shipment Of UHMWPE sheet Uhmwpe sheet shipped to Europe this week. UHMWPE(Ultra High Molecular Weight Polyethylene) has an incredible resistance to abrasion and can out perform almost any engineering plastic in this regard,UHMWPE sheet is well suited for applications that demand durability and low friction.UHMWPE sheet have outstanding abrasion resistance superior impact resistance and Exhibits virtually no water absorption. UHMWPE sheet self-lubricating properties excellent mechanical properties even in cryogenic conditions.UHMWPE is often described as the world's toughest polymer. UHMWPE is characterized by toughness, chemical resistance, low coefficient of friction, near zero moisture absorption, and easy processing. We provides custom plastic CNC machining service.We're your ideal partner to create precision machined prototypes and parts.