-

06-14 2024

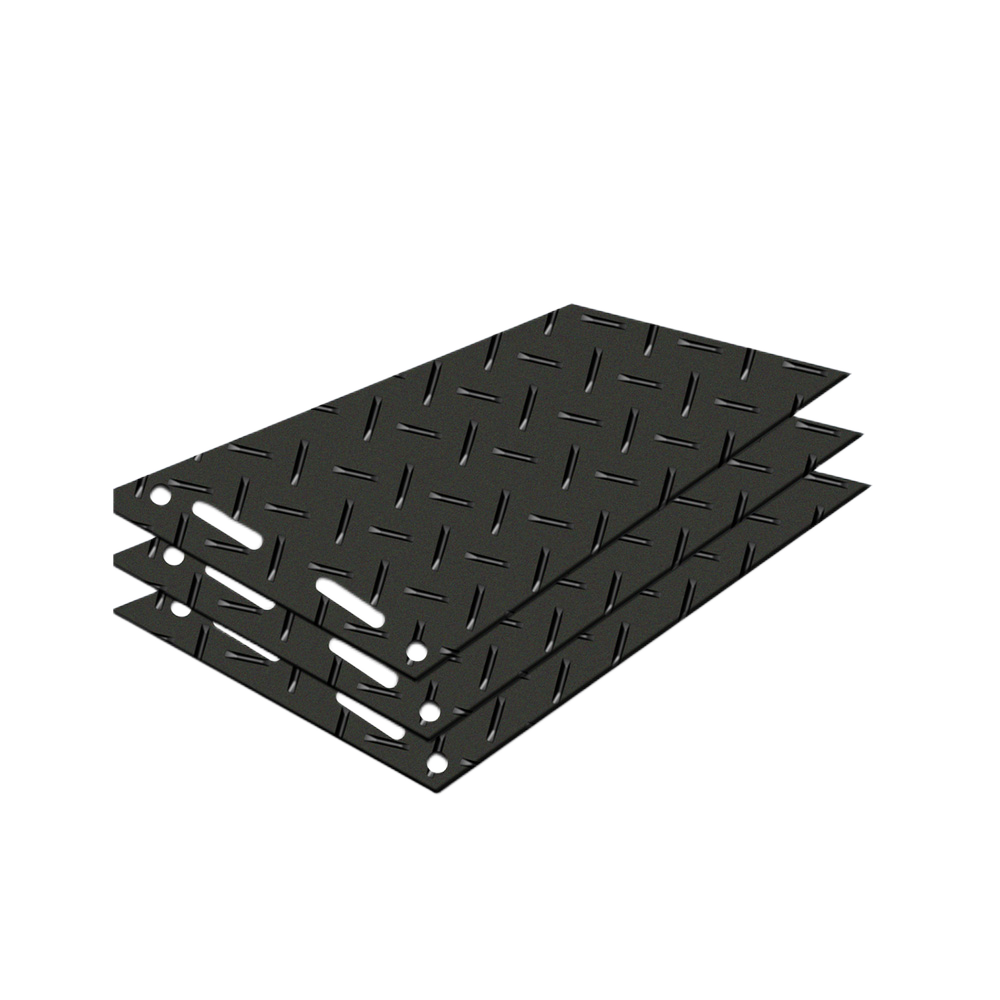

Temporary ground protection mats

Polyethylene temporary ground protection board is a high-density composite polyethylene board used in short-term and long-term project construction sites. High-density polyethylene temporary ground protection board is non-toxic, tasteless. It has good heat resistance and cold resistance, good chemical stability,high rigidity and toughness, and good mechanical strength. Dielectric properties and environmental stress cracking resistance are also good. Uhmwpe Plastic Road Mat is used to solve the impact of harsh environment such as road surface and weather to ensure construction progress and safety. Lawn protection cover mats has excellent properties such as light weight, high load-bearing,wear resistance, corrosion resistance. impact resistance. Good toughness, shock absorption.moisture resistance, etc. HDPE portable road mat is easy to lay, long life, and reusable. It is a green and environmentally friendly product.

-

06-05 2024

Uhmwpe Plastic Plate

The outstanding feature of ultra wear-resistant polyethylene sheet is its high wear resistance, which is very valuable in the application of many engineering equipment. Among all current engineering plastics, Uhmwpe Plastic Plate wear resistance is very high. As the molecular weight of ultra-high molecular weight polyethylene increases, this material becomes more abrasive. Our company has a highly educated professional R&D team, four advanced CNC hot pressing plate production lines, and a temperature control system using German Siemens automatic control technology to ensure product quality. Shandong Shengte'er Polyethylene Plastic Board is suitable for lining coal silos, material silos, funnels, and chutes in industries such as coal, metallurgy, steel, thermal power, cement, coking, glass, coal washing, and smelting. Hdpe Plastic Sheet can effectively solve the problems of coal silo and material silo blockage, bonding, and bridging that plague enterprise production. As long as you pay attention, you will find that the large enterprises around you can see the figure of Shandong Shengteer.

-

06-04 2024

HDPE Mats

Polyethylene plastic ground protection mat produced by Shandong Shengteer Polyethylene Anti slip Pavement Board Manufacturer is a brand that is commonly used in temporary roads, lawns, and other places in domestic and foreign engineering projects. The polyethylene anti slip pavement board is produced by Shandong Shengteer Source Factory, which is a non-standard customization and can be shipped within 3-5 days. Shandong Shengteer Ground Protection Mat is an ideal material for short-term and long-term project construction sites. Its sturdy protruding anti slip pattern solves the problem of vehicles and goods sliding and sinking, facilitating the evacuation of vehicles and factory movement. By using various connection methods, Uhmwpe Plastic Road Mat can adapt to different ground and weather conditions and various temporary road surfaces, and design dimensions according to the contour of the road surface, solving the problems of muddy and tilted roads. Different customers use HDPE portable road mat in different environmental environments, which determines the diversity of specifications for polyethylene anti-skid paving boards. Shandong Shengteer is a professional manufacturer of lawn protection cover mats, always thinking from the customer's perspective. Therefore, our HDPE Mats can adjust the mold size according to customer requirements and produce various sizes that customers need. Our strict quality control system and testing system ensure the qualified rate of products entering the warehouse.

-

05-31 2024

polyethylene-plastic-ground-protection-mat

Shandong Shengteer specializes in the production of plastic ground protection mat, which are sold both domestically and internationally. Shandong Shengteer has a strong supply of lawn protection cover mats from manufacturers with worry free procurement. When purchasing polyethylene temporary paving boards from us, you don't have to worry about quality or after-sales service. Our professional manufacturer provides one-stop after-sales service. Shandong Shengteer HDPE Mats is an ideal material for short-term and long-term project construction sites. Its sturdy protruding anti slip pattern solves the problem of sliding and sinking of vehicles and goods, facilitates the evacuation of vehicles and factory movement, and utilizes various connection methods to adapt to different ground and weather conditions and various temporary road surfaces. HDPE portable road mat follows the contour of the road surface for design dimensions, solving the problems of muddy and tilted roads. Shandong Shengteer plastic ground protection pads Factory has over 10 years of advanced production and research and development experience, and creates high-quality and cost-effective products for customers with a continuous improvement attitude. It has gained long-term trust from more than 1300 domestic and foreign customers.

-

05-29 2024

Comparison between polyethylene plastic ground protection mat and steel ground protection mat

Comparison between polyethylene plastic ground protection mat and steel ground protection mat It is said that Uhmwpe Plastic Road Mat are good, but what are the advantages? As a manufacturer of temporary road mats - Shandong Shengteer let our professionals tell you which one is better, polyethylene plastic paving boards or steel paving boards? 1、 Weight: heavy duty road mats is lightweight, one seventh the weight of the steel plate, and can be easily moved by two people, greatly reducing the workload during transportation. 2、 Safety: Steel plates are prone to lifting at all four corners during operation, which can cause injury to people; The four corners of the plastic swamp pads can be firmly adhered to the ground without lifting, and the polyethylene plastic pavement board itself has resilience, which can be restored after being bent for a period of time. 3、 Performance: Steel plates have excellent hardness in terms of wear resistance, which is comparable to lawn protection cover mats . However, other superior properties of HDPE portable road mat cannot be compared. 4、 Service life: Polyethylene plastic pavement boards have high costs, but they can still be used for up to ten years, while steel plates cannot be used for a year, with all four sides warping and even breaking. HDPE mat are prone to continuous bending under any pressure. Shandong Shengteer - a manufacturer of beach access mat with 20 years of production and sales experience, with various specifications, guaranteed quality, more favorable prices, and fast delivery speed. When purchasing construction mud mat,come to Shandong Shengteer the manufacturer of road plates, and we will definitely satisfy you!

-

05-28 2024

The application of Polyethylene Plastic Board in marine industry

The application of Polyethylene Plastic Board in marine industry In the marine industry, ultra-high molecular weight polyethylene sheets are widely used in marine equipment and weapon equipment to solve the problem of marine microbial contamination. The attachment and fouling of marine microorganisms can have a serious impact on ships, marine instruments, etc., increasing resistance, consuming fuel, accelerating corrosion, and blocking mesh and pipelines. Uhmwpe Plastic Plate has good corrosion resistance, non adhesion, and wear resistance. This sheet can effectively prevent the attachment of marine microorganisms, reduce fouling, and improve the service life and performance of equipment. For example, in the underwater part of a ship,Hdpe Plastic Sheet can be used to make the hull, reducing surface roughness, navigation resistance, and fuel consumption; In marine instruments, Uhmwpe Board can be used to manufacture protective coatings to protect instruments from microbial erosion and damage; In addition, ultra-high molecular weight polyethylene sheets can also be used for marine aquaculture cages, fixed fishing nets, etc., to prevent mesh blockage. Overall, the application of Uhmwpe Plastic board in the marine industry can improve the reliability and performance of marine equipment, reduce maintenance costs, and provide strong support for the development of the marine economy.