-

04-03 2025

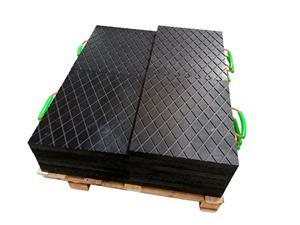

Production process of UHMWPE outrigger plate

Production process of UHMWPE outrigger plate The production of UHMWPE outrigger plate usually adopts compression molding process. The basic steps of the process include: 1. Preparation of raw materials: Polyethylene granules of very high purity are selected to ensure the quality of the final product. 2. Mixing and molding: The polyethylene granules are mixed evenly with the additives and then placed into the mold for high temperature and high pressure molding. Due to the high molecular weight of UHMWPE, special equipment and techniques are usually required to ensure that the material fills the mold evenly. 3. Cooling and Removal: The molded mat is cooled and removed from the mold, followed by post-processing. The post-processing may include grinding, trimming, etc. to ensure dimensional accuracy and surface smoothness. 4. Inspection and Packaging: The completed mat boards are subject to strict testing to ensure that their performance indicators meet the relevant standards, and then packaged and ready for shipment.

-

04-01 2025

Application areas of UHMWPE outrigger plate

Application areas of UHMWPE outrigger plate 1. Mining and heavy machinery: In mining, dock and other heavy-duty operations, UHMWPE outrigger plates can effectively carry heavy loads and reduce equipment damage and maintenance costs. 2. Aerospace and aviation: Because of its superior wear and impact resistance, UHMWPE outrigger plates are also used in part of the structure of the space shuttle and aircraft support components. 3. chemical and pharmaceutical industry: due to its excellent chemical stability, UHMWPE is widely used in chemical pipelines, tanks and pharmaceutical equipment. 4. construction and engineering: in construction, UHMWPE outrigger plates are commonly used in load-bearing structures and vibration-damping facilities, which can improve the safety and stability of the building. 5. Transportation and logistics: In logistics management, UHMWPE outrigger plates are used in forklifts, lifts and storage equipment to provide support and ensure the smooth progress of transportation.

-

03-17 2025

UHMWPE Crane pad

-

02-24 2025

UPE Crane Outrigger Pads

UPE Crane Outrigger Pads Crane outrigger pads are essential safety accessories that provide stability and support for cranes and other heavy lifting equipment on job sites. Choosing the right outrigger pads is crucial to ensure safe and efficient operations. In this article, we’ll explore the various types of crane outrigger pads available in the market, their unique characteristics, and their specific uses to help you make an informed decision for your lifting operations. Custom Outrigger Pads: In addition to standard options, many manufacturers offer custom outrigger pads tailored to specific requirements and preferences. Custom pads can be fabricated to precise dimensions, shapes, and configurations to fit unique outrigger setups and load conditions. Whether you need pads with reinforced corners, integrated handles, or color-coded markings, custom outrigger pads provide flexibility and versatility to meet your exact specifications. Working with a reputable supplier ensures that you get high-quality, custom solutions designed for optimal performance and safety.

-

12-04 2024

Crane outrigger pad

-

10-04 2024

UHMWPE Process Parts

UHMWPE Process Parts UHMWPE is often described as the world's toughest polymer. UHMWPE is characterized by toughness, chemical resistance, low coefficient of friction, near zero moisture absorption, and easy processing.We provides custom plastic CNC machining service.We're your ideal partner to create precision machined prototypes and parts. UHMWPE Process Parts compared to other solid thermoplastics, UHMW is lightweight and floats on water. Most importantly, UHMW machined parts are self-lubricating and have the highest impact and wear resistance of any thermoplastic. UHMWPE Process Parts Impact-resistant preservatives reduce stress and installation time. UHMWPE is a common plastic known for its extreme durability, versatility, and cost-effectiveness. You can also count on UHMW parts for their reliable wear, impact, and chemical resistance. Order your custom CNC machined UHMW parts today in just minutes.

-

09-26 2024

UHMWPE Outrigger Pads

-

09-20 2024

What can you make with UHMW parts?

What can you make with UHMW parts? UHMW is also easy to machine with common woodworking tools, one of the contributing factors to its cost-effectiveness. The truly surprising thing about parts made from UHMW is that they often outperform metal parts in specific applications. As with other plastics like HDPE, UHMW is an excellent fit for marine construction applications for things like dock fender pads, pile guards, and anti-skid walkways. Similarly, these two materials tend to replace wood in these scenarios and they do not rot, splinter, or corrode like wood.

-

07-19 2024

Outrigger Pad

-

06-28 2024

Why create outrigger pads?