The Development Space of Ultra High Molecular Weight Polyethylene Shaped Parts

The material of UHMWPE shaped parts is mainly UHMWPE, which has higher mechanical properties than ordinary HDPE (unit: g/cm3 or kg/m3). The dielectric properties and environmental stress cracking resistance of the polymer polyethylene lining board are also good. It has outstanding impact resistance, stress cracking resistance, high-temperature creep resistance, low friction coefficient, self-lubrication, excellent chemical corrosion resistance, fatigue resistance, noise (dB) damping, nuclear radiation resistance, etc.

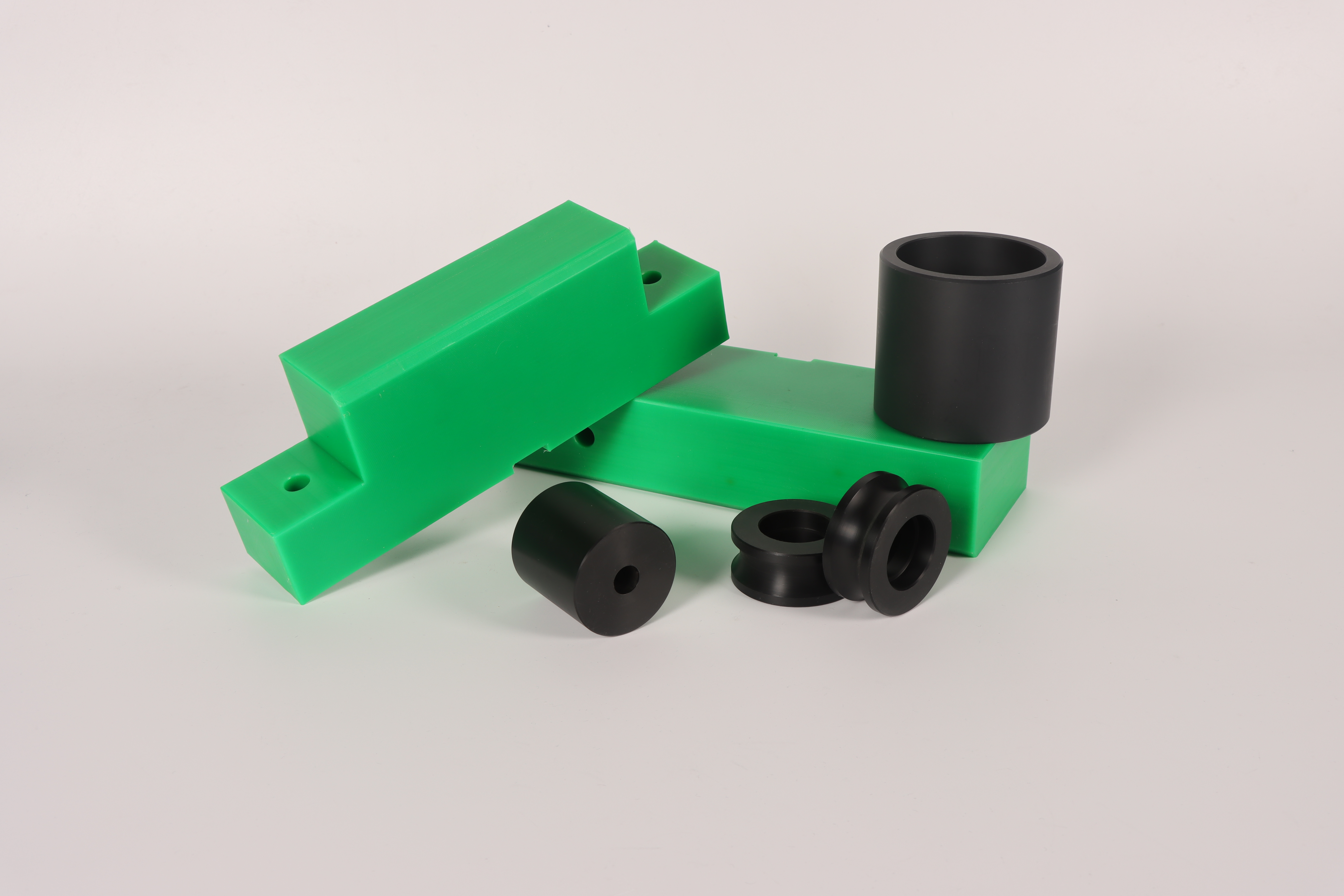

In recent years, with the continuous breakthroughs in UHMWPE processing technology, UHMWPE shaped parts have been applied in general machinery, food machinery, chemical industry, medical equipment, entertainment supplies, and other fields. It is also used in small snow removal machines, storage devices, and TTW guide products for vacuum dryers. With the development of processing technology, the application field of UHMWPE will continue to expand.

UHMWPE has become one of the irreplaceable materials for the production of HDPE shaped parts. However, shaped parts also play a crucial role, so UHMWPE shaped parts have a large market space. At present, the demand for ultra-high molecular weight polyethylene shaped parts has greatly increased, occupying a certain share in the industry.