Wear Resistance And Impact Resistance Of UHMWPE

Wear Resistance And Impact Resistance Of UHMWPE

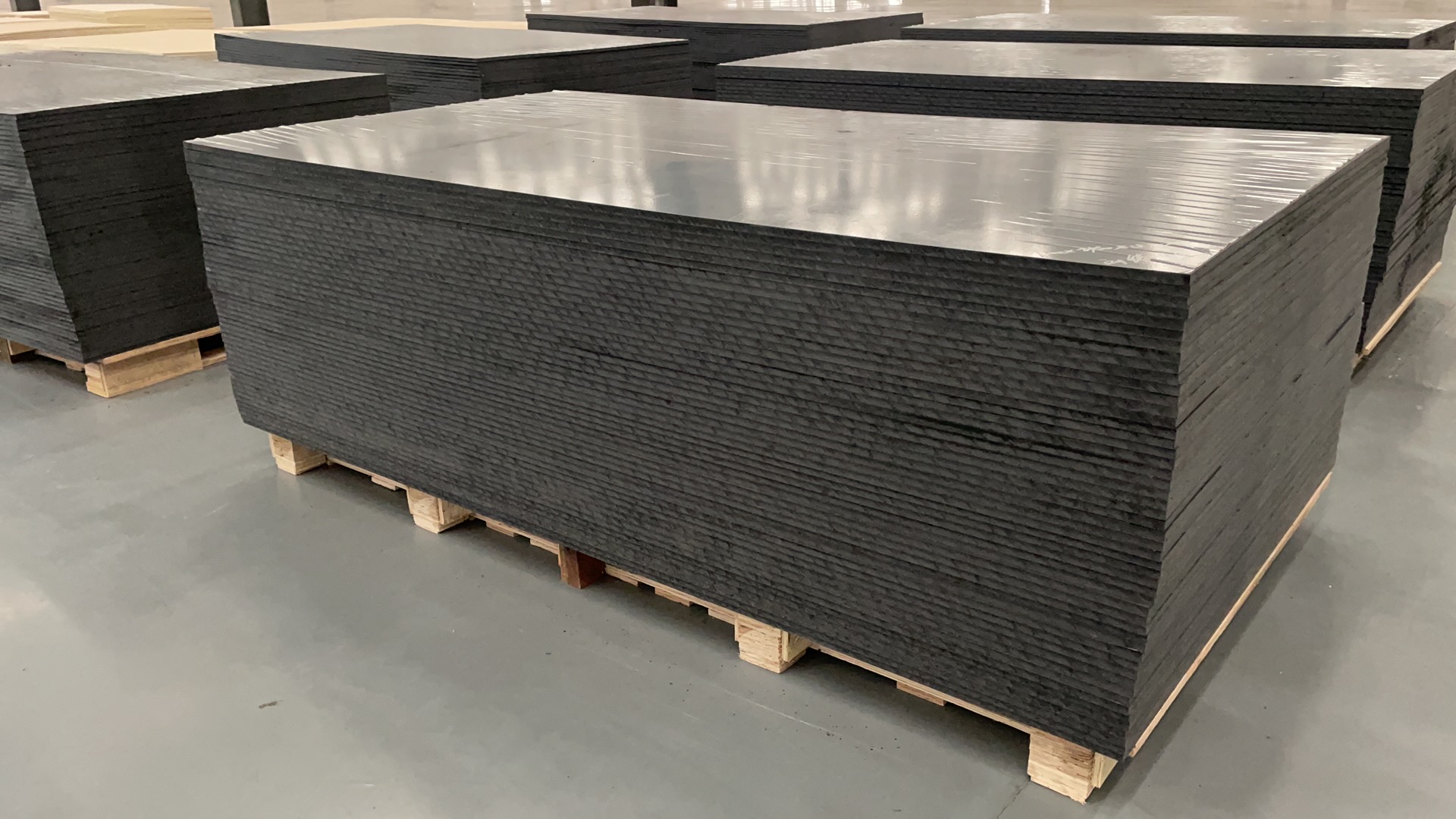

UHMWPE is the engineering plastic with the best comprehensive performance at present. Its advantages such as wear resistance and impact resistance are mainly manifested in the following application fields.

1) Textile machinery

At present, an average of 30 UHMWPE parts are used in each textile machinery abroad, such as shuttle pickers, shuttle rods, gears, couplers, flower sweeping rods, buffer blocks, eccentric wheels, rod sleeves, swing back beams and other impact-resistant wear parts.

2) Papermaking machinery

At present, the amount of UHMWPE used in papermaking machinery accounts for 10% of the total, such as using UHMWPE to manufacture paper machine wipers, water suction box covers, guide plates, hydrofoils, compression parts, joints, sealing shafts, guide plates, scrapers, filters, etc.

3) Packaging machinery

UHMWPE can be used to make gears, cams, impellers, rollers, pulleys, bearings, bushings, sleeves, pins, gaskets, seals, elastic couplings, screws, pipe clamps, etc. Such as protective plates for docks and bridge piers.