Engineer plastic PE 1000 2000 500 HMWPE UHMWPE Sheet

Brand STE PLASTIC

Product origin ShanDong China

Delivery time Within 15 Days

Supply capacity Factory Direct Supply

UHMW product reduces noise from impact & vibration. It is a self-lubricating material that is chemical, corrosion, and wear-resistant. And its food safe. The weight is light, the is 1/8 of the rolled steel. Life is higher than steel. The wear resistance is 3 to 7 times of carbon steel and stainless steel.

UHMW-PE is a super engineering plastic that is probably not as well known as some other engineering plastics but can out perform its relatives in a number of important areas.

UHMWPE offers a combination of excellent properties outstanding abrasion resistance, superior impact resistance, non-sticking and self-lubricating properties and excellent mechanical properties, even in cryogenic conditions.

| 100% Virgin Polyethylene UHMWPE Sheet Supplier | |

| Material | UHMW |

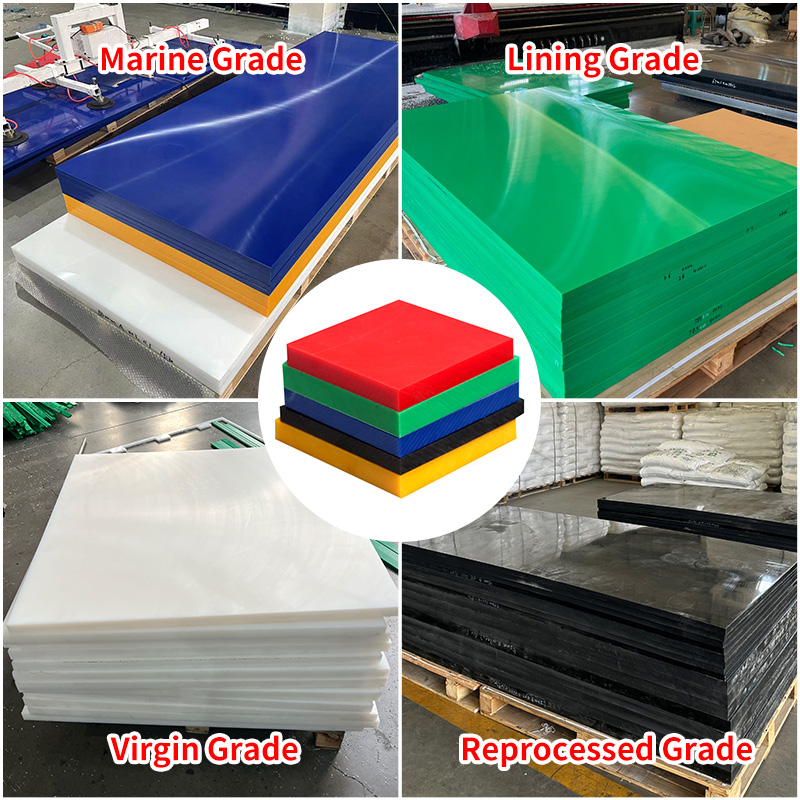

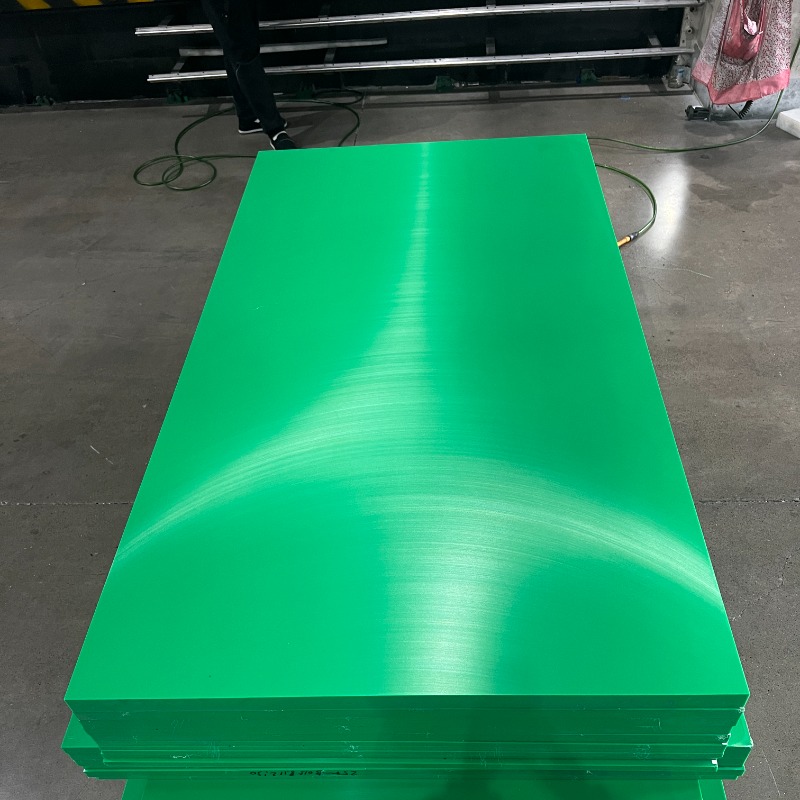

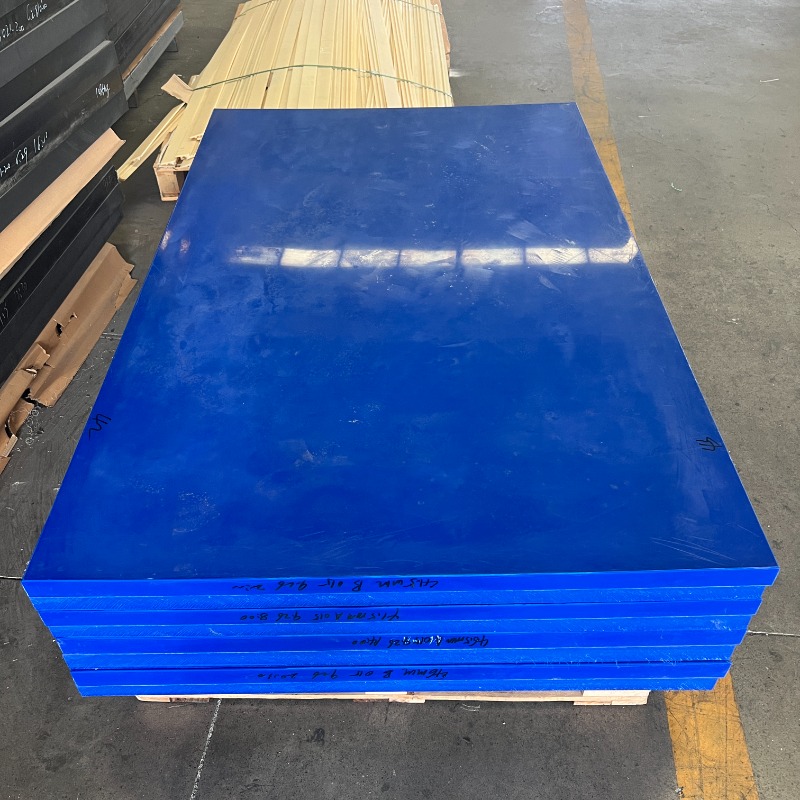

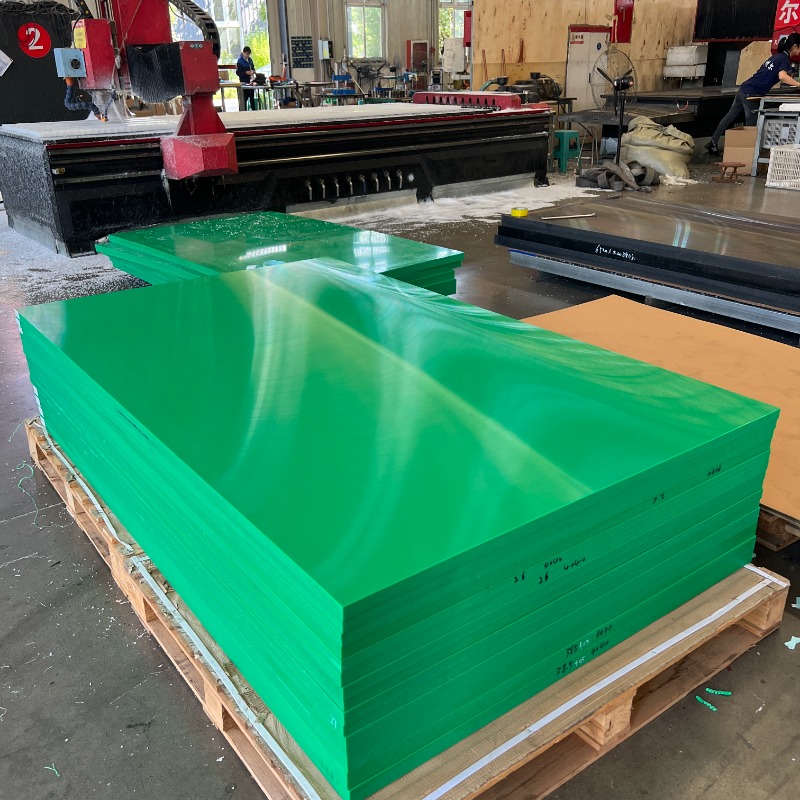

| Color | White,black,green,red and grey |

| Shape | Sheet, board, block, rod, tube |

| Size | Size Customized |

| Application | Mechanical, chemical, metallurgical, mining ect |

|

Package |

Pallet or as your requirements |

| Project |

UHMWPE / HDPE |

PTFE |

PA |

POM |

| Density (g/cm3) |

0.96 |

2.2 |

1.25 |

1.45 |

| Minimum operating temperature(℃) |

-269 |

-180 |

-40 |

-40 |

|

Maximum working temperature (℃) |

80 |

220 |

110 |

110 |

| Tensile breaking strength (Mpa) |

32 |

10 |

25 |

5.3 |

| Tensile elongation at break (%) |

320 |

100 |

200 |

25-75 |

| Average wear rate (%) |

1 |

4 |

3-5 |

6 |

| Impact strength (KJ/M) |

≥140 |

16 |

6-11 |

8-13 |

| Water absorption (%) |

<0.01 |

<0.02 |

1.5 |

0.25 |

| Friction factor |

0.07-0.11 |

0.04-0.1 |

0.15-0.4 |

0.15-0.35 |

| Non-toxicity | Y |

N |

Y |

Y |

UHMWPE Application:

1. Chemical Engineering: Corrosion and wear resistantance mechanical parts

2. Thermal power: coal handling, storage of coal, warehousing chute lining

3. Concrete: cement raw and finished product silo silo lining

4. Coal processing: sieve plate, filter, U-underground coal chute

5. Grain: food storage or chute lining

6. Mining: sieve plate, chute linings, wear anti-bonding part

7. Food industry: star-shaped wheel, transmission timing bottle screw, bearings, guide rollers, guides, slide blocks, etc.