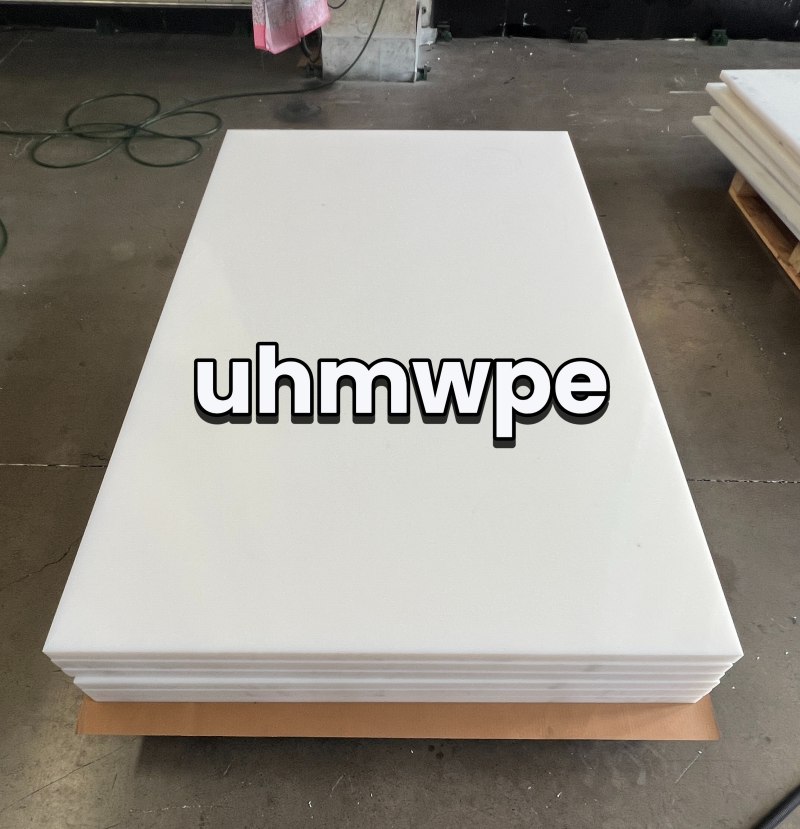

Natural polyethylene UHMWPE plastic sheet

Brand STE PLASTIC

Product origin ShanDong China

Delivery time Within 15 Days

Supply capacity Factory Direct Supply

This natural UHMW is used where sliding abrasion occurs or where metal parts meet, causing friction or abrasion wear. It is excellent for chute and hopper liners, conveyor components, wear pads, machine guides, impact surface, and guide rails.

UHMWPE is a kind of polyethylene with a molecular weight of more than 9 million, making it far superior to any other thermoplastic for wear resistance, and by far one of densest polymers available, outperforming even carbon steel for wear applications.

Name | Natural polyethylene UHMWPE plastic sheet |

Material | UHMWPE |

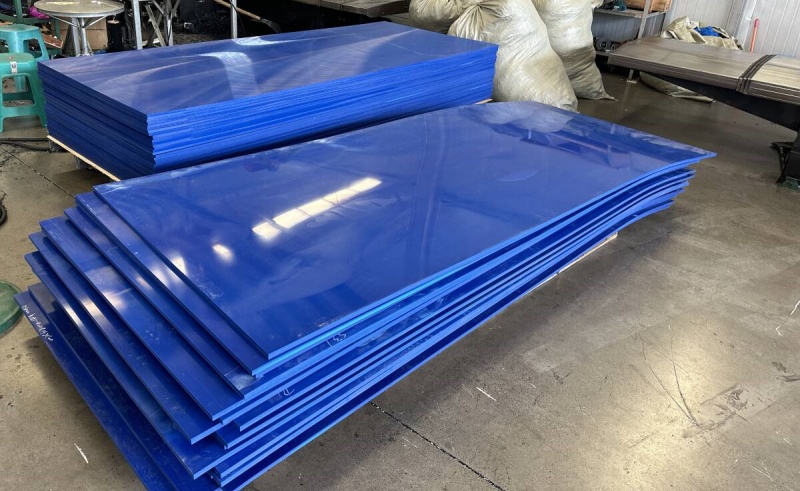

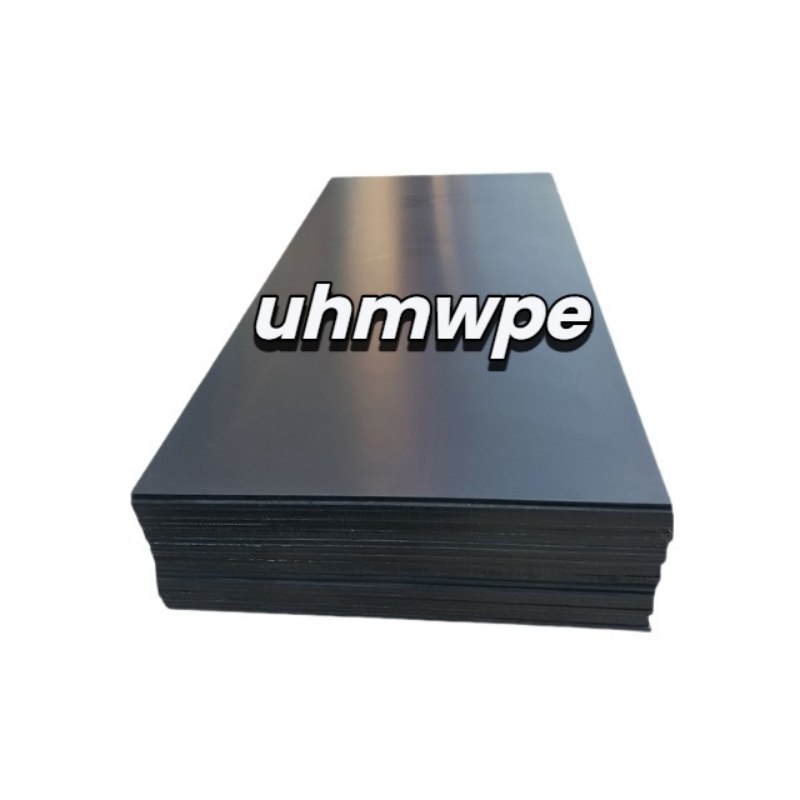

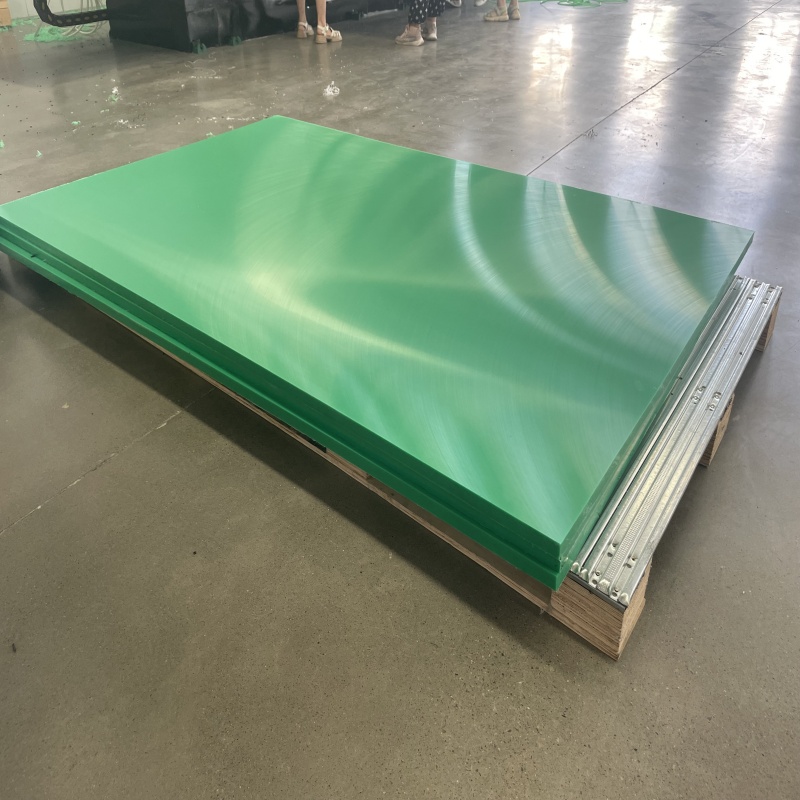

| Color | White,black,green,nature,blue,yellow,etc |

| Diameter | 5-200mm,or customized |

| Condition | In stock/Made to order |

| Free Sample | Available |

| Shape | Sheet, rod, tube, gear, rack,pulley, guide rail, Plastics fittings,and so on. |

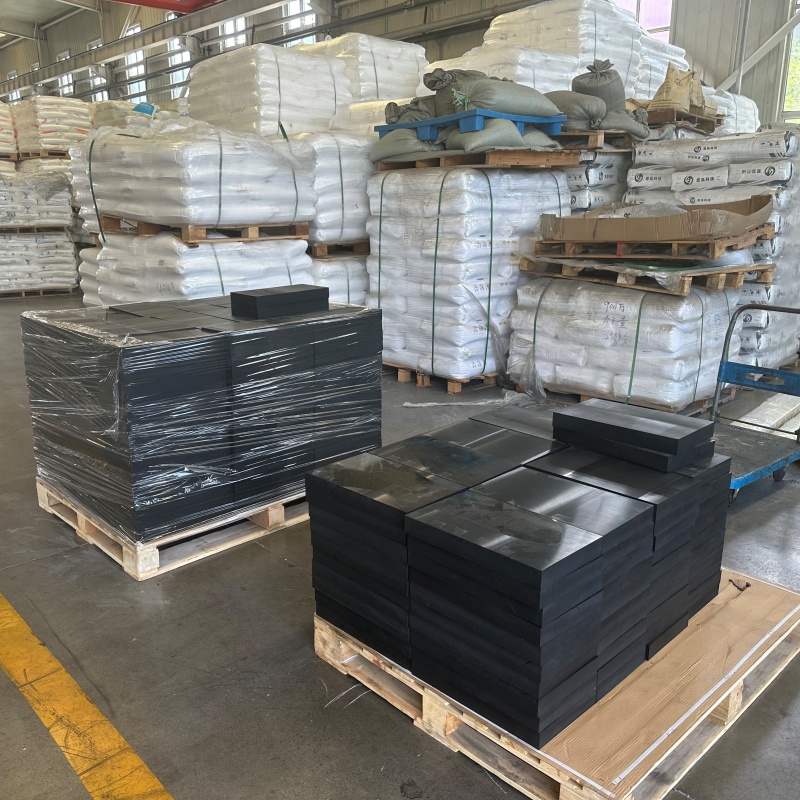

| Packing | Plastic bags,Cartons,Wodden case,Pallet,Container,ect. |

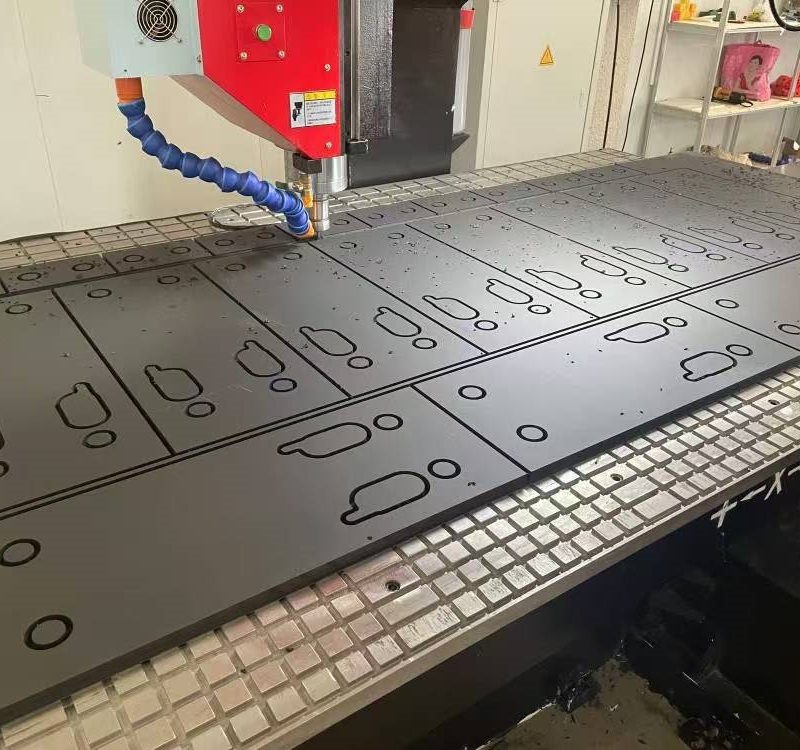

The UHMWPE sheets is produced using superior UHMWPE raw materials through an molding process, and then cooled and shaped for 48 hours to reduce the amount of deformation, and then subjected to CNC custom processing and angular smoothing. The UHMWPE sheets will then be tested by FQC and then packaged and shipped according to customer requirements.

Features of UHMWPE (Ultra High Molecular Weight Polyethylene) Sheets:

1.Best shock resistance even in low temperature

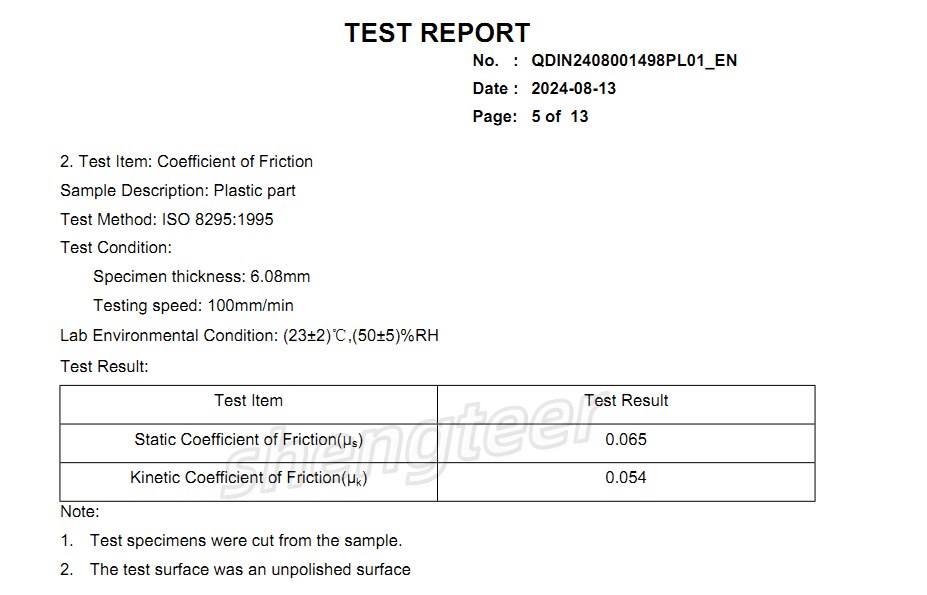

2.Low frictional factor, and well sliding bearing material

3.Lubricity (no caking, in adhesion)

4.Best chemical corrosion resistance and stress craze resistance

5. machinery process ability

6.Lowest water absorption

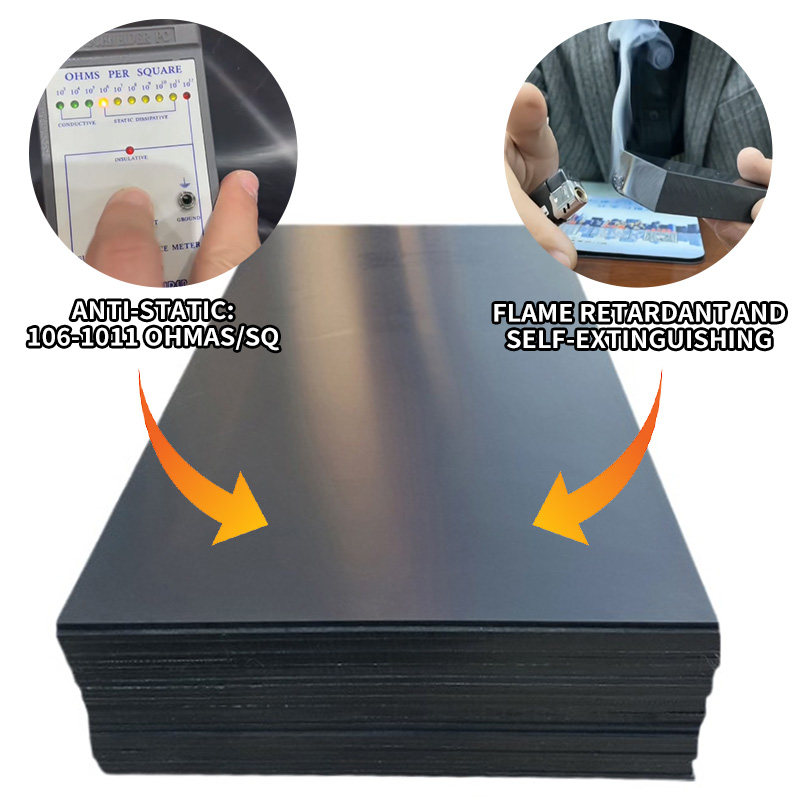

7.Excellent electric insulativity and anti-static behavior

8.Nice high energy radioactive resistance

9.Abrasive resistance which always have in thermoelectricity polymer

10.Density is lower than other thermoplastic