Self-lubricating UHMWPE Or HDPE Conveyor Wear Strips

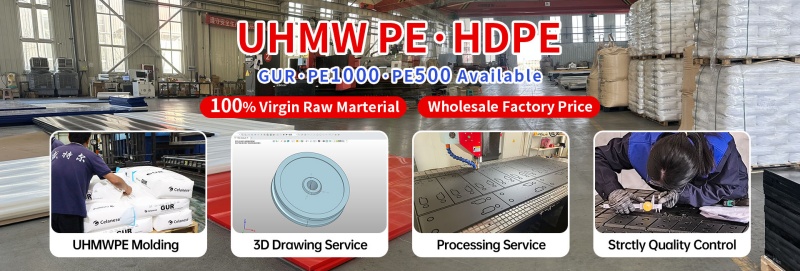

Brand STE PLASTIC

Product origin shandong china

Delivery time Within 15 Days

Supply capacity Factory Direct Supply

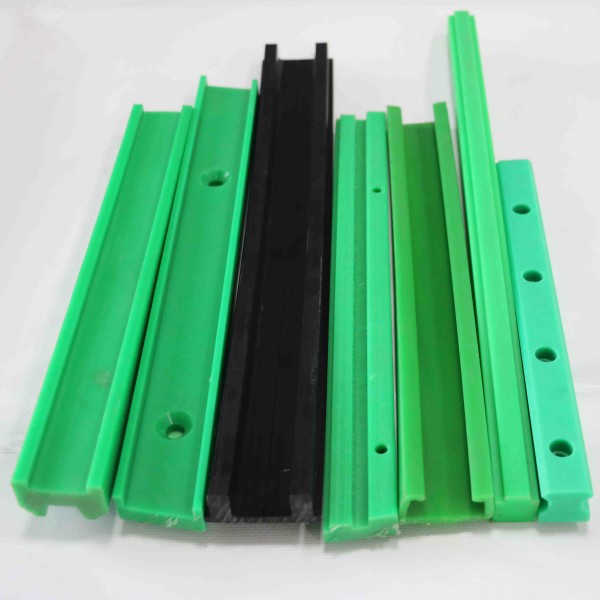

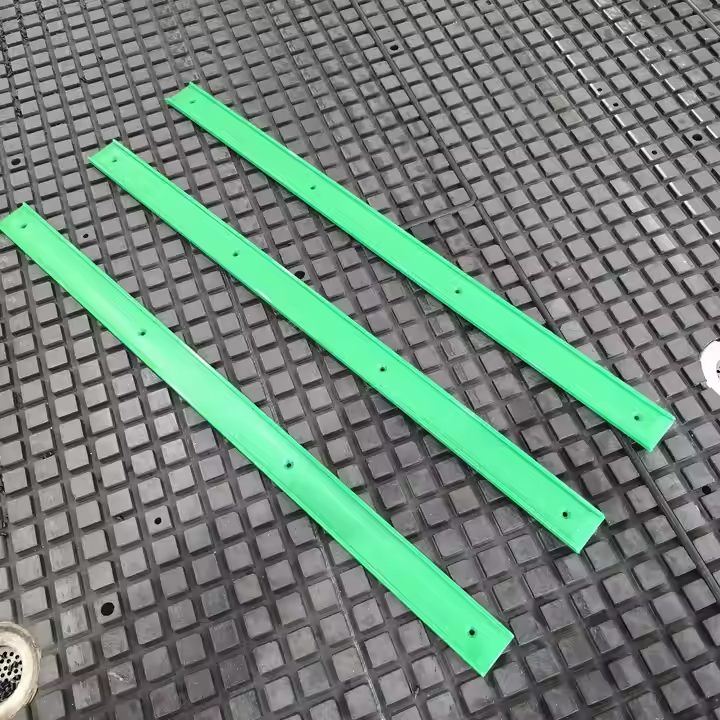

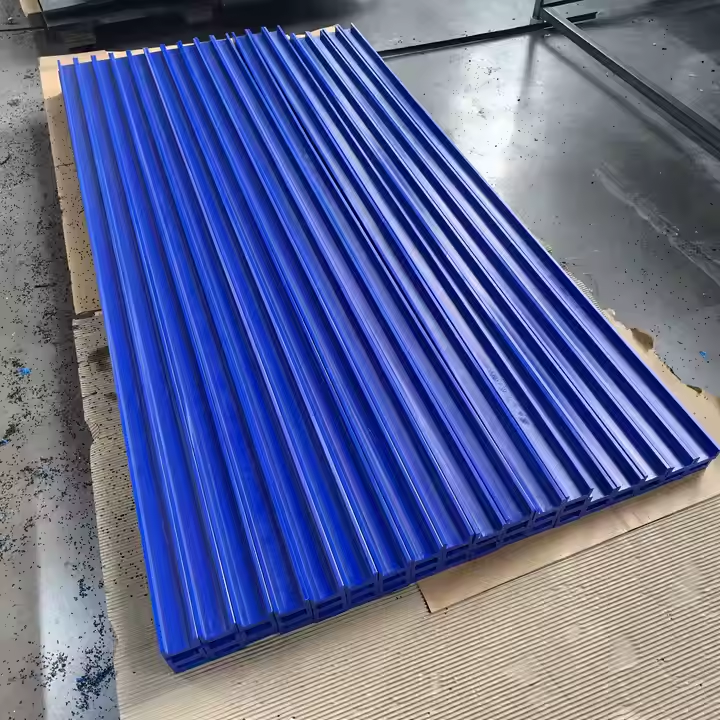

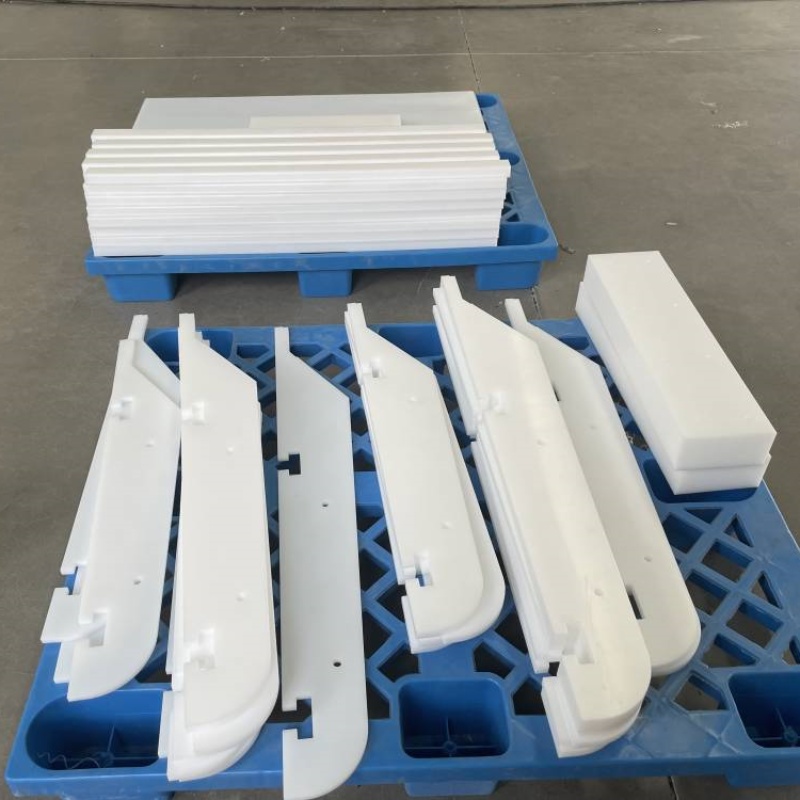

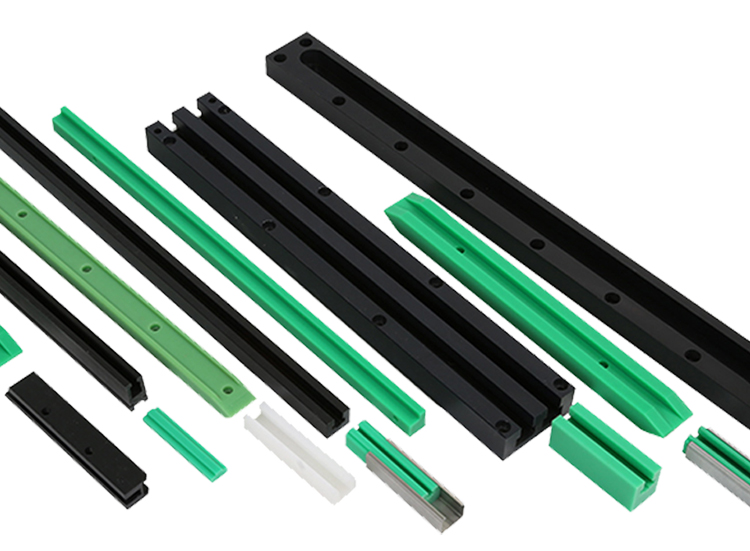

Ultra high molecular weight polyethylene(UHMWPE) wear-resistant strip, extruded from UPE/HDPE/UHMWPE plastic material, also known as chain guide rail, plastic guide rail, lining strip, cushion strip, and friction strip, greatly reduces the hard friction between the conveyor belt and the frame, effectively extending the service life of the conveyor belt.

There are various types of lining strips, including direct embedded ones and many flat plates with different widths and thicknesses. Widely used in chain conveyor equipment to support and guide the chain, preventing chain detachment and tooth jamming during long-distance transportation.

The UHMWPE wear-resistant chain guide rail has the following characteristics:

1. High impact strength, especially low temperature impact strength.

2. Strong wear resistance, its wear resistance is 5 times that of nylon 66 and polytetrafluoroethylene, and 7 times that of carbon steel.

3. The friction coefficient is small, only 0.07-0.11, and has good self-lubrication.

4. Good non adhesion, easy to clean surface adhesion.

5. The chemical properties are stable, and the vast majority of inorganic, organic acids, alkalis, salts, and organic solvents are not corrosive to ultra-high molecular weight polyethylene.

6. It has excellent aging resistance, and its aging life is more than 50 years under natural light.

7. Completely hygienic and non-toxic, ultra-high molecular weight polyethylene is suitable for industries such as food and medicine that require high hygiene conditions.

8. Low density and light weight. Easy to handle and install.

Application:

UHMWPE wear resistant strips can replace materials such as carbon steel, stainless steel, bronze, etc. for use in textile, papermaking, food machinery, transportation, medical, coal mining, chemical and other sectors. For example, impact and wear resistant parts in Textile manufacturing, such as shuttle, shuttle rod, gear, coupling, broom, buffer block, eccentric block, rod sleeve, swing effect, etc. In the paper industry, box covers, scraper plates, compression components, joints, guide wheels, scrapers, filters, etc. are used.