-

08-06 2024

What is two color hdpe sheet?

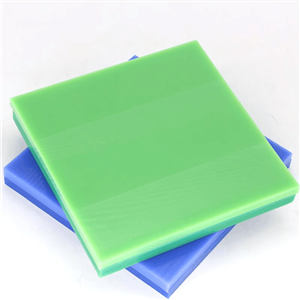

What is two color hdpe sheet? Our high-density polyethylene (HDPE) sandwich panel is a versatile, durable, and color-fast plastic commonly used in signage applications. It has environmental andultraviolet stability, can withstand the harshest outdoor conditions, and can be used in areas that are frequently cleaned or frequently exposed to humid environments. Anti-scratch UV sandwich panel with UV stability, resistance to deterioration in harsh outdoor environments and markings with pens, markers and spray paint Our HDPE sandwich two-color board has a variety of specifications and a variety of matching colors to choose from. Custom colors can be provided according to customized orders. Has the following characteristics: Anti-acid, anti-odor. moisture-proof,anti-mildew Very easy to manufacture and process Weather resistance, impact resistance Environment and UV stable Excellent resistance to acids, alcohols and alkalis

-

07-06 2024

Polyethylene boron-containing board is not only anti-radiation, but also has all the characteristics of UHMWPE

Polyethylene boron-containing board is not only anti-radiation, but also has all the characteristics of UHMWPE We are production and research and development in shielding polyethylene materials for many years . It is widely used in nuclear power. space radiation protection,military. aerospace, medical and other fields. We can do 5%-30% Boron-containing polyethylene board and can be customized according to the drawings.Polyethylene boron-containing board is made by adding boron powder to ultra-high molecular weight polyethylene, which is processed by stirring,kneading, and plasticizing. Boron is a trace alloy element that can absorb fast neutrons and achieve a good combination with plastics. The effect of shielding neutrons.

-

06-26 2024

Why use HDPE board instead of wood?

Why use HDPE board instead of wood?

-

06-19 2024

Advantages of UHMWPE board

Advantages of UHMWPE board UHMWPE sheet is a kind of magical plastic in people's eyes. Because Uhmwpe Plastic Plate has strong wear resistance, it is more wear-resistant than steel. weathering, anti-aging, self-lubricating, very low friction coefficient, excellent chemical resistance and corrosion resistance, superior impact resistance, and high tensile strength.Non-toxic, odorless, anti-ultraviolet, flame-retardant; relatively low water absorption. no adhesion, light weight, easy to operate and maintain, not rot, cracking or cracking;100% recyclable. UHMWPE boards are used in many fields. In the past, Hdpe Plastic Sheet was mainly used for liners, truck liners,coal liners. cement silo liners, and grain silo liners. Now it will be more and more widely used. With the advent of the energy shortage of steel, more and more fields have begun to choose plastic instead of steel. If you needs wear-resistant, impact-resistant, self-lubricating,and corrosion-resistant products. please feel free to contact us for details.

-

06-17 2024

What is the performance of UHMWPE marine fender?

What is the performance of UHMWPE marine fender?

-

06-05 2024

Uhmwpe Plastic Plate

The outstanding feature of ultra wear-resistant polyethylene sheet is its high wear resistance, which is very valuable in the application of many engineering equipment. Among all current engineering plastics, Uhmwpe Plastic Plate wear resistance is very high. As the molecular weight of ultra-high molecular weight polyethylene increases, this material becomes more abrasive. Our company has a highly educated professional R&D team, four advanced CNC hot pressing plate production lines, and a temperature control system using German Siemens automatic control technology to ensure product quality. Shandong Shengte'er Polyethylene Plastic Board is suitable for lining coal silos, material silos, funnels, and chutes in industries such as coal, metallurgy, steel, thermal power, cement, coking, glass, coal washing, and smelting. Hdpe Plastic Sheet can effectively solve the problems of coal silo and material silo blockage, bonding, and bridging that plague enterprise production. As long as you pay attention, you will find that the large enterprises around you can see the figure of Shandong Shengteer.

-

05-28 2024

The application of Polyethylene Plastic Board in marine industry

The application of Polyethylene Plastic Board in marine industry In the marine industry, ultra-high molecular weight polyethylene sheets are widely used in marine equipment and weapon equipment to solve the problem of marine microbial contamination. The attachment and fouling of marine microorganisms can have a serious impact on ships, marine instruments, etc., increasing resistance, consuming fuel, accelerating corrosion, and blocking mesh and pipelines. Uhmwpe Plastic Plate has good corrosion resistance, non adhesion, and wear resistance. This sheet can effectively prevent the attachment of marine microorganisms, reduce fouling, and improve the service life and performance of equipment. For example, in the underwater part of a ship,Hdpe Plastic Sheet can be used to make the hull, reducing surface roughness, navigation resistance, and fuel consumption; In marine instruments, Uhmwpe Board can be used to manufacture protective coatings to protect instruments from microbial erosion and damage; In addition, ultra-high molecular weight polyethylene sheets can also be used for marine aquaculture cages, fixed fishing nets, etc., to prevent mesh blockage. Overall, the application of Uhmwpe Plastic board in the marine industry can improve the reliability and performance of marine equipment, reduce maintenance costs, and provide strong support for the development of the marine economy.

-

05-21 2024

Why is ultra-high molecular weight polyethylene sheet highly popular among users?

Why is ultra-high molecular weight polyethylene sheet highly popular among users?

-

05-08 2024

Application of UHMWPE Sheet in Self lubrication and Non viscosity

Application of UHMWPE Sheet in Self lubrication and Non viscosity 1. Material storage and transportation. Uhmwpe Plastic Plate can be used to manufacture powder liners, such as silos, hoppers, chutes, sliding surfaces, rollers, and other return devices. The lining plate of the storage hopper is used for the lining of the storage hopper, such as coal hopper and powder product storage hopper. 2. Agricultural and engineering machinery.Hdpe Plastic Sheet can be used to manufacture wear-resistant plates and brackets for agricultural tools. 3. Sports equipment. Polyethylene Plastic Board can be used to manufacture skateboards and skateboard trailers.

-

05-06 2024

HDPE sheet, widely used with good chemical corrosion resistance

HDPE sheet, widely used with good chemical corrosion resistance UHMWPE sheet has good chemical corrosion resistance. Except for concentrated nitric acid and concentrated sulfuric acid, UHMWPE pad will not corrode in all alkaline and acidic solutions.UHMWPE board can be used in concentrated hydrochloric acid at 80 ℃, stable in 20% nitric acid and 75% sulfuric acid, and stable in washing water and solution. However, ultra-high molecular weight polyethylene is prone to swelling in aromatic or halogenated materials, especially at higher temperatures, so special attention should be paid to its application. The application of high molecular weight polyethylene sheets, with corrosion resistance and non water absorption as the main factors, is as follows:, 1. Container packaging. The use of UHMW polyethylene to manufacture warm water containers for solar energy equipment is one of the widely used fields of UHMWPE. 2. Chemical equipment. UHMW polyethylene is used in the manufacturing of chemical components, such as sealed packaging boards, packaging materials, vacuum molds, pump components, bearing bushings, gears, seal assemblies, etc. 3. Transportation pipeline