-

10-22 2024

Wear Resistance And Impact Resistance Of UHMWPE

Wear Resistance And Impact Resistance Of UHMWPE UHMWPE is the engineering plastic with the best comprehensive performance at present. Its advantages such as wear resistance and impact resistance are mainly manifested in the following application fields. 1) Textile machinery At present, an average of 30 UHMWPE parts are used in each textile machinery abroad, such as shuttle pickers, shuttle rods, gears, couplers, flower sweeping rods, buffer blocks, eccentric wheels, rod sleeves, swing back beams and other impact-resistant wear parts. 2) Papermaking machinery At present, the amount of UHMWPE used in papermaking machinery accounts for 10% of the total, such as using UHMWPE to manufacture paper machine wipers, water suction box covers, guide plates, hydrofoils, compression parts, joints, sealing shafts, guide plates, scrapers, filters, etc. 3) Packaging machinery UHMWPE can be used to make gears, cams, impellers, rollers, pulleys, bearings, bushings, sleeves, pins, gaskets, seals, elastic couplings, screws, pipe clamps, etc. Such as protective plates for docks and bridge piers.

-

10-19 2024

The Application Of UHMWPE board

The Application Of UHMWPE UHMWPE is known as a "magic material" internationally. Its self-lubricating, non-stick, corrosion-resistant, and non-water-absorbing properties are mainly used in the following aspects: 1) Material storage and transportation UHMWPE can be used to make powder linings, such as: silos, hoppers, chutes and other return devices, sliding surfaces, rollers, etc.; silo linings of coal hoppers, powdered product hoppers and other silo linings. 2) Agricultural and engineering machinery UHMWPE can be used to make anti-wear plates and brackets for agricultural tools. 3) Sports and cultural supplies UHMWPE can be used to make ice skating sleds, sled draggers, etc. 4) Chemical equipment UHMW-PE is used to manufacture chemical parts, such as sealing packing, packing, vacuum mold boxes, pump parts, bearing bushings, gears, sealing joints, etc. 5) Transportation pipelines

-

09-24 2024

UHMWPE sheet

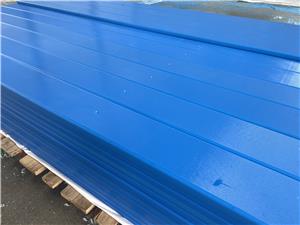

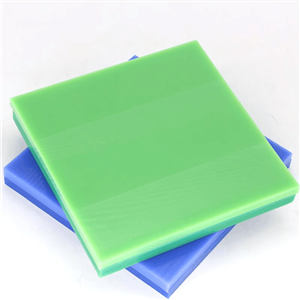

UHMWPE sheet UHMW is a common plastic known for extreme durability, versatility, and cost-effectiveness. You can also count on UHMW parts to be reliably abrasion, impact, and chemical resistant. Discover the ultimate solution for your engineering, construction, and agricultural needs with our premium-grade polyethylene sheets. Engineered for durability, flexibility, and resistance to water and chemicals. Embrace the versatility and reliability of our polyethylene sheets to elevate your projects

-

09-17 2024

What is UHMW?

What is UHMW? Our Ultra High Molecular Weight Polyethylene, or UHMW for short, was crafted as a unique solution for projects that needed durability, low friction, and chemical resistance. That means it’s used most often in wear applications that need a longer lifespan. UHMW is self-lubricating, which ensures smooth and noiseless operations. Known for its extremely high molecular weight, it features an unsurpassed combination of slickness, toughness, and impact resistance.

-

08-23 2024

High wear resistance plastic—UHMWPE sheet

UHMWPE has become a kind of magical plastic by people,not only its impact resistance and self-lubrication resistance but also its corrosion resistance and wear resistance. UHMWPE sheet used for many field.before most used for liner, truck liner.coal liner.cement warehouse liner, grain warehouse liner,now application will be more and more widespread.With the advent of steel energy shortage, more and more fields are choose plastic instead steel. If your industry are need the wear resistance, impact resistance, self-lubrication.corrosion resistance products, free to contact us for details.

-

08-06 2024

What is two color hdpe sheet?

What is two color hdpe sheet? Our high-density polyethylene (HDPE) sandwich panel is a versatile, durable, and color-fast plastic commonly used in signage applications. It has environmental andultraviolet stability, can withstand the harshest outdoor conditions, and can be used in areas that are frequently cleaned or frequently exposed to humid environments. Anti-scratch UV sandwich panel with UV stability, resistance to deterioration in harsh outdoor environments and markings with pens, markers and spray paint Our HDPE sandwich two-color board has a variety of specifications and a variety of matching colors to choose from. Custom colors can be provided according to customized orders. Has the following characteristics: Anti-acid, anti-odor. moisture-proof,anti-mildew Very easy to manufacture and process Weather resistance, impact resistance Environment and UV stable Excellent resistance to acids, alcohols and alkalis

-

07-06 2024

Polyethylene boron-containing board is not only anti-radiation, but also has all the characteristics of UHMWPE

Polyethylene boron-containing board is not only anti-radiation, but also has all the characteristics of UHMWPE We are production and research and development in shielding polyethylene materials for many years . It is widely used in nuclear power. space radiation protection,military. aerospace, medical and other fields. We can do 5%-30% Boron-containing polyethylene board and can be customized according to the drawings.Polyethylene boron-containing board is made by adding boron powder to ultra-high molecular weight polyethylene, which is processed by stirring,kneading, and plasticizing. Boron is a trace alloy element that can absorb fast neutrons and achieve a good combination with plastics. The effect of shielding neutrons.

-

06-26 2024

Why use HDPE board instead of wood?

Why use HDPE board instead of wood?

-

06-19 2024

Advantages of UHMWPE board

Advantages of UHMWPE board UHMWPE sheet is a kind of magical plastic in people's eyes. Because Uhmwpe Plastic Plate has strong wear resistance, it is more wear-resistant than steel. weathering, anti-aging, self-lubricating, very low friction coefficient, excellent chemical resistance and corrosion resistance, superior impact resistance, and high tensile strength.Non-toxic, odorless, anti-ultraviolet, flame-retardant; relatively low water absorption. no adhesion, light weight, easy to operate and maintain, not rot, cracking or cracking;100% recyclable. UHMWPE boards are used in many fields. In the past, Hdpe Plastic Sheet was mainly used for liners, truck liners,coal liners. cement silo liners, and grain silo liners. Now it will be more and more widely used. With the advent of the energy shortage of steel, more and more fields have begun to choose plastic instead of steel. If you needs wear-resistant, impact-resistant, self-lubricating,and corrosion-resistant products. please feel free to contact us for details.

-

06-17 2024

What is the performance of UHMWPE marine fender?

What is the performance of UHMWPE marine fender?